Prevention and correction of side bending problem in NC plasma cutting medium and thick plate narrow and long workpiece

Introduction

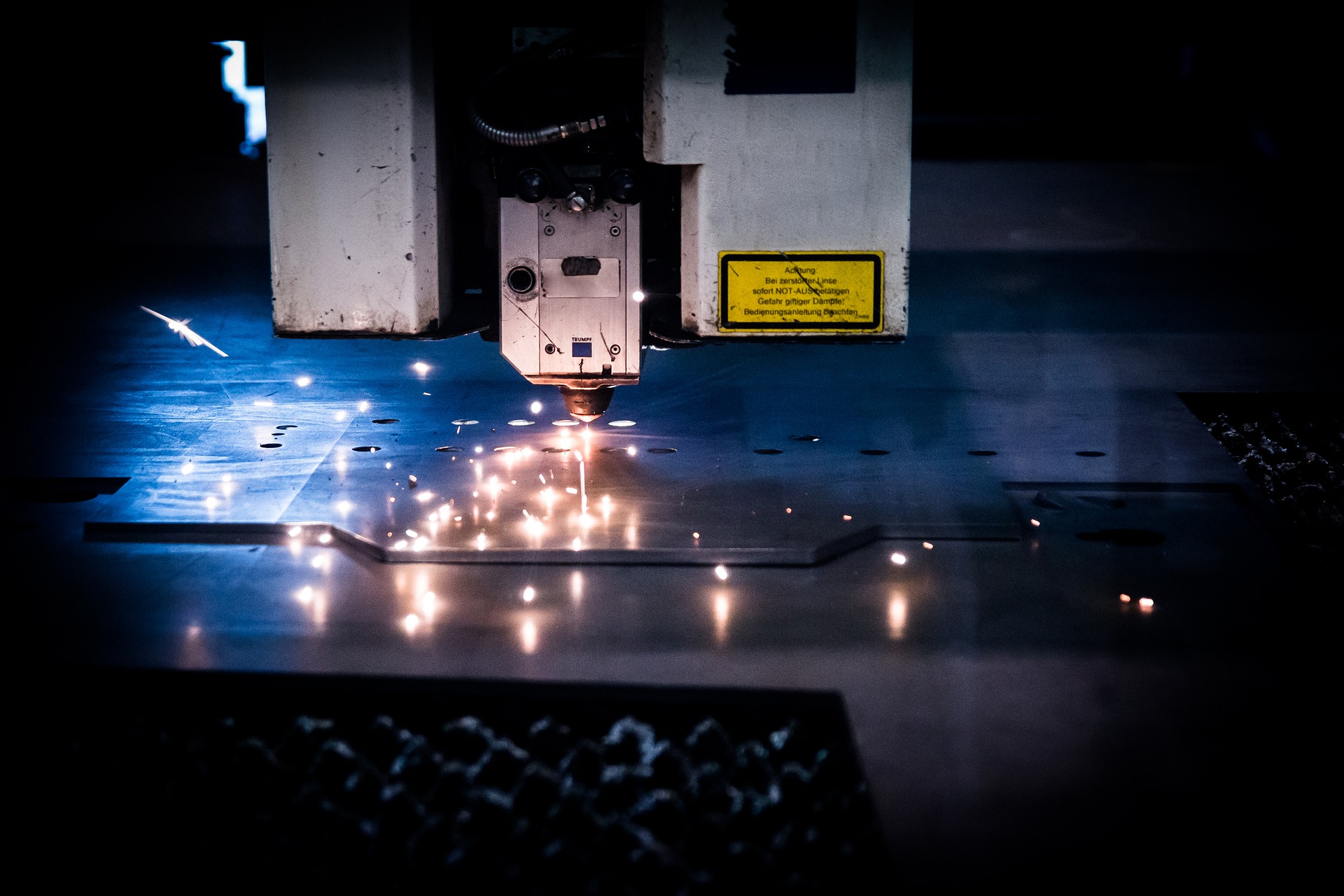

As a plate separation equipment with high processing efficiency and stable quality, NC plasma cutting machine is widely used in the production of steel structure of electric locomotive. In the production practice, it is found that the side bending phenomenon often occurs in the narrow and long workpiece of medium and heavy plate after NC plasma cutting, which seriously affects the product quality. This paper mainly describes several prevention methods of side bending problems that have been fully verified in the production process, which can effectively improve the production efficiency and ensure the product quality.

Numerical control plasma cutting machine is a kind of high-efficiency processing equipment whose running track is controlled by numerical control system. It uses the gas heated to extremely high temperature and highly ionized to transfer the arc power to the workpiece, the high heat melts the workpiece, and the high-speed gas blows the slag down to form slits. It has certain advantages in cost and efficiency in the processing of thin plate and medium plate.

Cause analysis and influence of workpiece side bending

There is a large amount of heat input in the cutting process of medium and heavy plates. At the same time, due to the high cost of long-term natural aging treatment or repeated roll leveling, the residual internal stress of metal plates is difficult to avoid. Therefore, the stress release in the cutting process will lead to the deformation offset of narrow and long workpieces with different degrees and difficult to control in the direction. Because the plates of NC plasma cutting machine are generally placed on the equipment workbench in the way of tiling, It is found that there is no additional deformation in the middle part of the workpiece by using the gravity clamping device in production, so it is possible to clamp the workpiece in the middle part by using the gravity clamping device.

The workpiece side bending will mean that the straightness is seriously out of tolerance, which brings great difficulties to the groove preparation or welding assembly in the next process. Therefore, the side bending must be controlled in the workpiece separation process.

Several methods of preventing and correcting workpiece side bending

Veneer double gun cutting

In order to avoid side bending of narrow and long workpieces of medium and thick plates during cutting, the two cutting guns of NC plasma can be set to single plate and double gun mode during long edge cutting, as shown in Figure 2. This method can ensure that the heat input is roughly the same when cutting the long side of the workpiece, and can effectively avoid the generation of side bending of the workpiece.

Set up micro connection

During the preparation of NC plasma cutting, micro connections can be set at intervals on the long side of the workpiece to support the workpiece in the form of lacing. When the deformation of the plate is caused by heat input and internal stress release of the plate, the micro connection lacing will ensure that the deformation of the plate is controllable and effectively avoid the generation of side bending, as shown in Figure 3.

Flame modification

The narrow and long workpiece of medium and thick plate with side bending can be adjusted by flame modification. The specific operation method is as follows: first, use fine cotton thread or nylon thread to find the measurement reference point at both ends of the length direction of the workpiece, then measure the span and interval according to the total length of the workpiece, measure the fine line size of the plate edge distance, carry out flame modification according to the size measurement results, and adjust the side bend of the workpiece.

Allowance processing

For some important parts with high requirements for straightness and workpiece edge quality, the allowance machining process can be selected, the allowance size can be set with reference to the empirical value of side bending deformation, and the allowance can be removed by planing or milling later. This method has high cost, so it is only used for important workpieces.

Comparison of several ways of preventing or correcting workpiece side bending

Veneer double gun cutting

Advantages: from the perspective of cost control, the single board double gun mode can save nearly half of the processing time without adding additional processes, and the effect of controlling side bending is good.

Disadvantages: single board double gun mode: first, there are requirements for production equipment, and the equipment without double cutting head cannot be produced in this way; Second, there are requirements for NC cutting programming software. If there are no relevant functions during programming, it is difficult to realize single board double gun cutting.

Set up micro connection

Advantages: Micro connections are set at intervals on the long side of the workpiece, and the form of supporting the workpiece in the form of lacing can fully avoid the side bending of the workpiece.

Disadvantages: first, the micro connection mode will add additional processes. After the NC cutting, the micro connection must be cut off, which is time-consuming and laborious, and a special blanking area must be prepared; Second, the surface quality of the position where the micro connection is manually cut is poor compared with the NC cutting edge, which may have an adverse impact on the welding group and component paint in the subsequent process.

Flame modification

Advantages: low cost and flexible mode.

Disadvantages: first, the side bend measurement must be carried out before the flame modification, which increases the additional workload. Second, due to the uncertainty of flame modification shrinkage, it requires high skills of operators and low operation efficiency.

Allowance processing

Advantages: the reserved machining method can obtain better edge quality of the workpiece, and the size can be fully guaranteed.

Disadvantages: the first is to add additional processes and prolong the product delivery cycle; Second, due to the unpredictability of workpiece side bending, it is difficult to formulate an economic allowance value.

Concluding remarks

This paper introduces several methods to prevent and correct the side bending problem in NC plasma cutting medium and thick plate narrow and long workpiece, which have different advantages, disadvantages and application scope, and should be selected in combination with the actual production situation.

add wechat

add wechat