Hydraulic precision leveling machine, also known as hydraulic leveling machine, hydraulic leveling machine, this model is Mahatma for non-ferrous metal sheet, mirror sheet, sheet metal parts, stamping parts, laser cutting parts and flame cutting parts, etc. A straightening machine designed and produced for plates, sheets and parts that require high surface finish.

The hydraulic Sheet Metal Flattening Machine adopts an additional row of intermediate rolls between the upper and lower rows of leveling work rolls and support bearings (wheels), forming a roller group structure of two or three layers each, totaling four or six layers; The leveling roller has uniform force distribution, good structural rigidity, small bending deformation of the work roller, high leveling accuracy, and harmonic attenuation straightening.

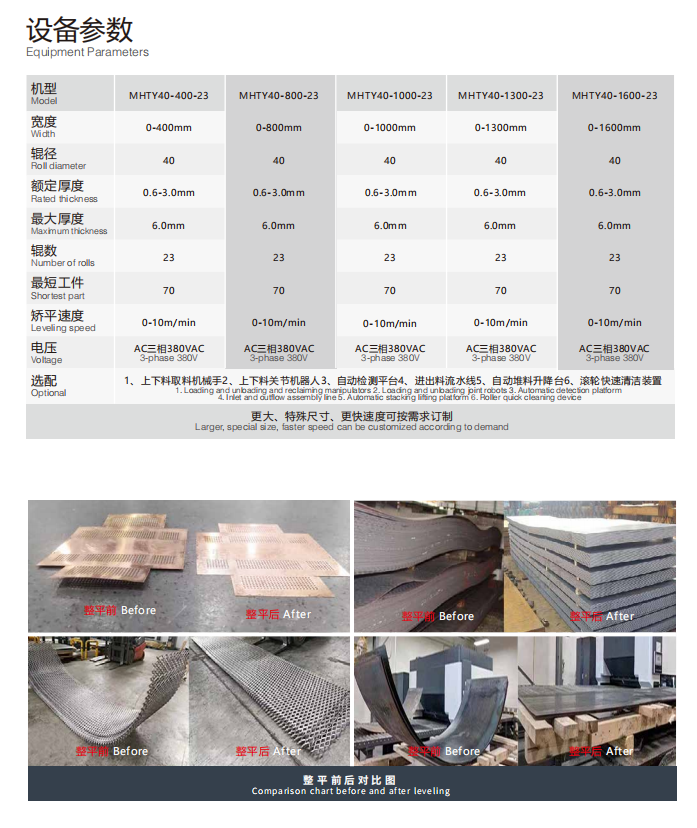

The leveling roller is supported to the best extent and has a very small distance between each other. The integrated leveling gap adjustment device ensures that the leveling gap remains constant throughout the entire leveling process, including when the cross-sectional area of the part changes. Even those difficult to level combustion cutting parts are not a problem, as they can be made flat and almost stress free in just a few minutes. Fundamentally solve the common problems of unevenness, easy roll imprint indentation, workpiece collapse, sickle bending, etc. in ordinary leveling, improve the accuracy of sheet metal correction, have a wide range of applications, and the material surface will not leave roll imprints, resulting in higher correction accuracy.

Equipment performance:

1. The powerful hydraulic pressure keeps the gap (mechanical dead limit) between the upper and lower leveling rollers constant, ensuring consistent correction effect for large quantities of parts;

2. 7-inch high-precision touch screen display, PLC control, visual input, editing, modification, and storage of process parameters;

3. Stamped parts, plates, and parts can be made flat and almost stress free in just a few minutes.

4. Precision sheet flattening machine is a metal plate that has been repeatedly bent through a large number of staggered leveling rollers, and the bending amount can be adjusted to achieve the required bending plan for leveling, so it does not damage the appearance of the plate.

5. After repeated bending of the metal plate, the length of the metal fibers gradually becomes consistent, and the internal stress of the material is eliminated at the same time. The metal plate is naturally flattened

6. Many users use cutting methods to achieve flatness, and using precision leveling machines can save a lot of materials

7. Due to the use of continuous and repeated bending technology, the precision leveling machine has greatly improved the leveling efficiency and entered the continuous production line, saving a lot of labor costs and breaking away from the technical dependence of traditional leveling experience

This product draws inspiration from the principles of Swiss HRC precision leveling machine and German ARKU (Aku) precision leveling machine, adopts innovative design ideas and advanced manufacturing processes, filling the gap in domestic precision leveling equipment for plate and sheet parts.

The performance fully meets the leveling capabilities of Swiss HRC precision flattening machines and German ARKU precision leveling machines. While ensuring quality, we will try our best to control manufacturing costs to meet your company's procurement budget.

Functional features:

1. There are many leveling rollers with precise arrangement,

2. The application of multiple auxiliary support rollers ensures that the leveling roller does not bend when subjected to force.

3. The strong hydraulic pressure keeps the gap between the upper and lower leveling rollers uneven.

4. A hydraulic press structure with good rigidity minimizes the overall deformation of the machine during operation.

5. The space on the right side of the equipment is open for easy roll changing and cleaning.

6. Vertical independent electric control box, touch screen control, easy to operate.