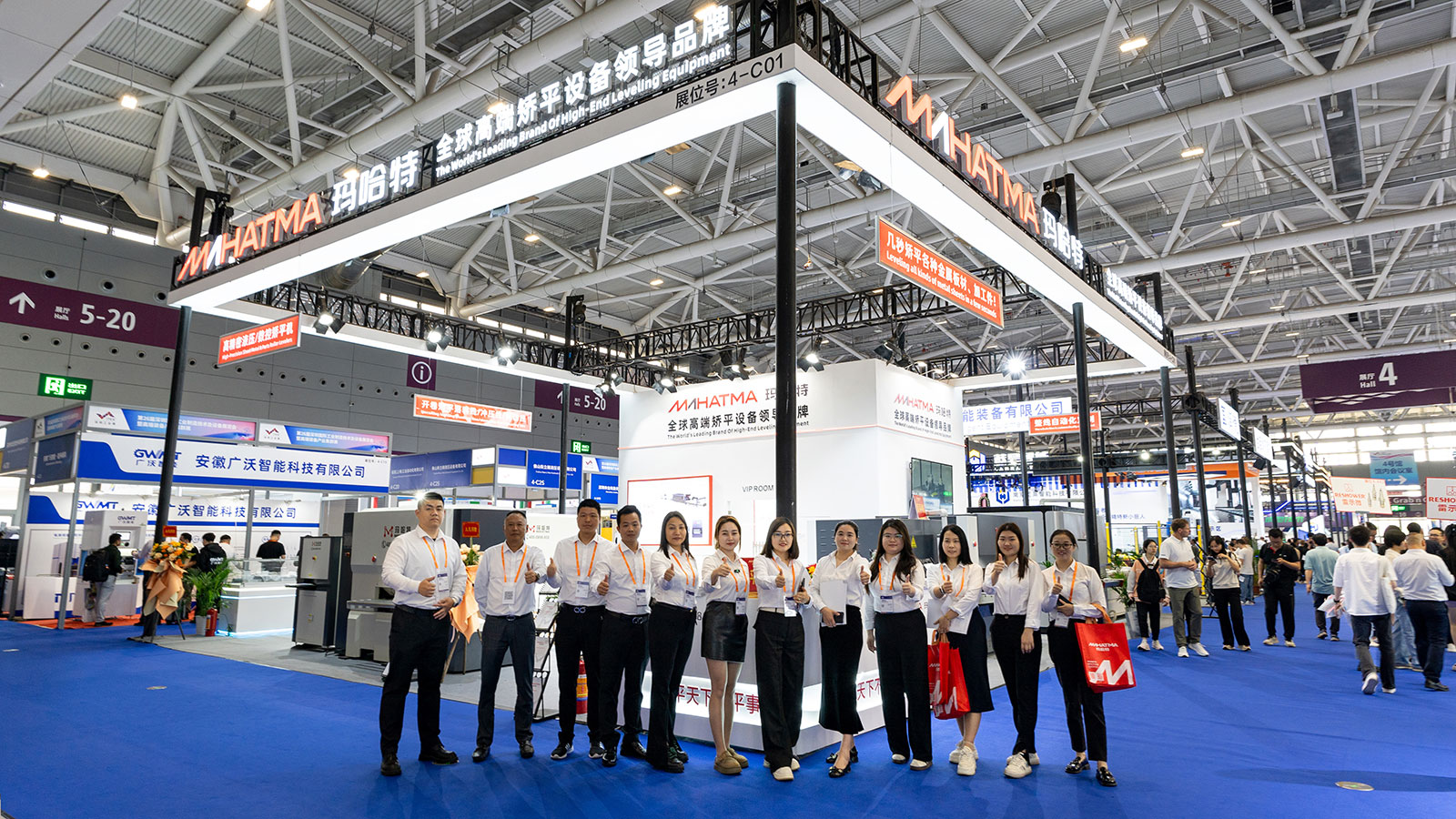

Steel coil straightening machines

Steel coil straightening machines are specialized equipment that are used to straighten and level steel coils. These machines are widely used in various industries such as automotive, construction, and manufacturing for the purpose of ensuring that steel coils are flat and have the necessary level of precision required for their intended use.

There are many different types of steel coil straightening machines available, each designed to meet specific needs and requirements. Some of the most common types include roller straighteners, rotary straighteners, and hydraulic straighteners. Each of these machines utilizes different techniques to straighten steel coils, and they have different levels of precision and efficiency.

Roller straighteners are the most basic type of steel coil straightening machine. They use a series of rollers to bend the steel coil back into a flat shape. These machines are relatively simple and inexpensive, and they are suitable for use with a wide range of coil sizes and thicknesses. However, they lack the precision and control of more advanced straightening machines, and they are not suitable for use with high-strength materials.

Rotary straighteners are a more advanced type of steel coil straightening machine. They use a series of rotating rollers to apply pressure to the steel coil, gradually bending it back into a flat shape. Rotary straighteners are capable of handling larger coils and thicker materials than roller straighteners, and they offer greater precision and control. However, they are more complex and expensive than roller straighteners, and they require more maintenance and upkeep.

Hydraulic straighteners are the most advanced type of steel coil straightening machine. They use hydraulic pressure to apply force to the steel coil, gradually straightening it out. Hydraulic straighteners are capable of handling very large coils and very thick materials, and they offer the highest level of precision and control. However, they are also the most complex and expensive type of straightening machine, and they require skilled operators to use them properly.

Regardless of the type of steel coil straightening machine used, the basic process of straightening steel coils involves three main steps: feeding the coil into the machine, straightening the coil, and then cutting the coil to the desired length. The feeding process is typically automated, using a conveyor or other system to move the coil into the machine. The straightening process involves applying pressure to the coil, gradually bending it back into a flat shape. Once the coil is straightened, it is typically cut to the desired length using a shear or other cutting tool.

There are many factors to consider when choosing a steel coil straightening machine, including the size and thickness of the coils to be straightened, the level of precision required, and the available space and budget. It is important to choose a machine that is appropriate for the particular application, as using the wrong type of machine can result in poor quality output, wasted materials, and increased costs.

In addition to straightening steel coils, some steel coil straightening machines are also capable of performing other functions such as cutting, punching, and forming. These machines are often used in conjunction with other equipment to create finished products such as automotive parts, construction materials, and industrial machinery.

In conclusion, steel coil straightening machines are essential equipment for many industries that rely on steel coils for their products. These machines are available in a wide range of types and configurations, each designed to meet specific needs and requirements. Choosing the right type of steel coil straightening machine is essential for achieving high-quality output, minimizing waste, and maximizing productivity and efficiency.

扫一扫添加微信

扫一扫添加微信