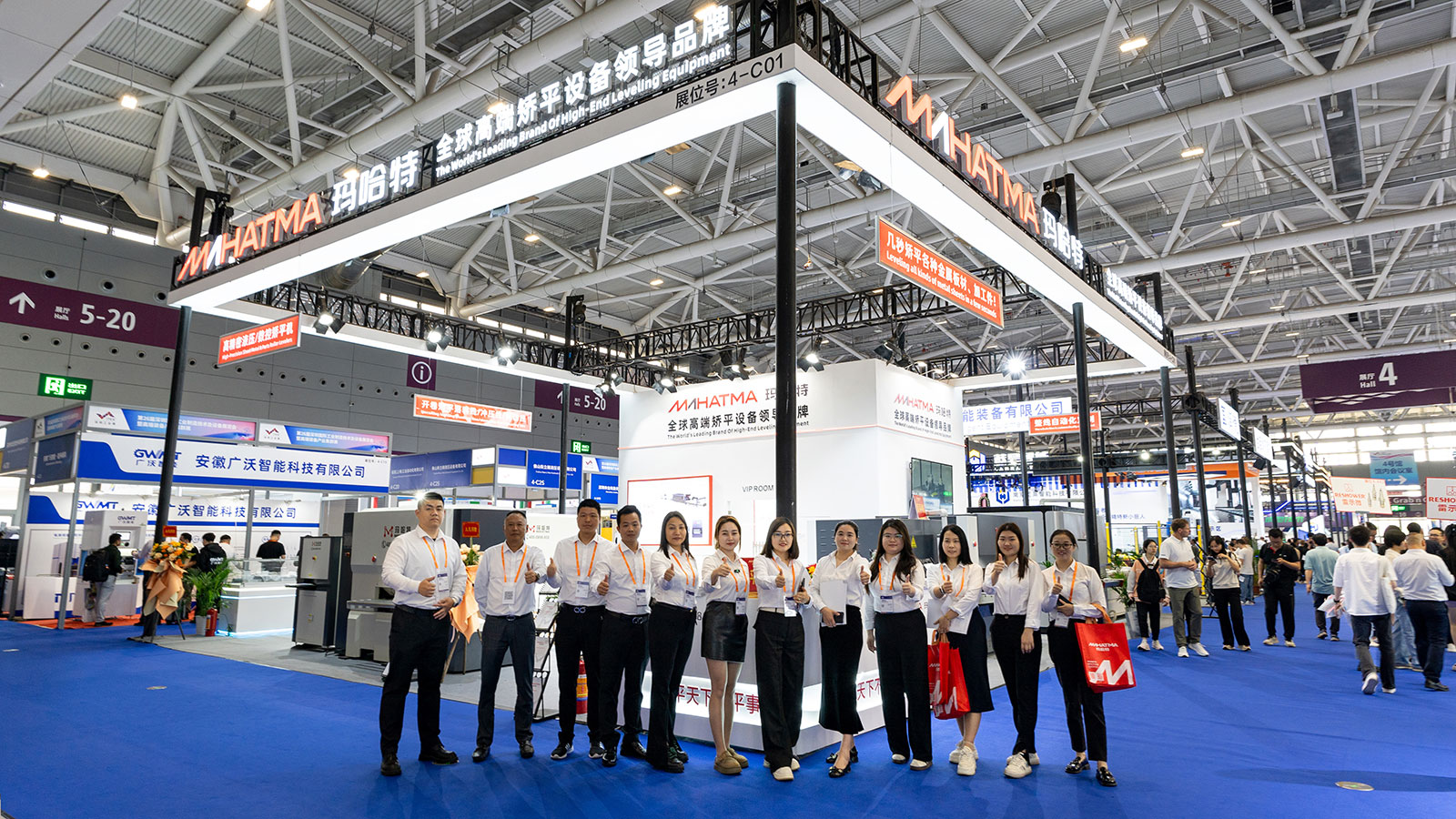

MAHATMA Plate Leveller

In various industries, achieving accuracy and precision is of paramount importance. Whether it's construction, woodworking, or metalworking, ensuring that surfaces are level and stable is crucial for the success of any project. This is where a plate leveller comes into play. A plate leveller is a versatile tool designed to level and balance plates or other objects, providing a reliable foundation for further work. In this comprehensive introduction, we will delve into the various aspects of plate levellers, including their functionality, types, applications, and benefits.

At its core, a plate leveller is a device that ensures objects are level and balanced. It consists of a flat, sturdy base equipped with an adjustable leveling mechanism. This mechanism allows users to modify the height or angle of the plate, thereby achieving a level surface. By making precise adjustments, plate levellers guarantee stability and accuracy in any given application.

Types of Plate Levellers:

Plate levellers come in various designs to cater to different needs and applications. The most common types include:

1. Manual Plate Leveller: This type requires manual adjustments to level the plate accurately. It is a cost-effective option suitable for small-scale projects.

2. Hydraulic Plate Leveller: Hydraulic plate levellers employ hydraulic systems to provide smooth and precise leveling. This type is ideal for heavy-duty applications that demand high accuracy.

3. Automatic Plate Leveller: Automatic plate levellers utilize advanced technology, such as sensors and motors, to automatically level the plate. They are often integrated into large-scale manufacturing processes to ensure consistent and efficient operations.

Applications:

The versatility of plate levellers makes them indispensable across a wide range of industries. Here are some key applications:

1. Construction: Plate levellers are extensively used in construction projects to level surfaces before laying flooring, erecting walls, or installing heavy equipment. They ensure stability and prevent structural issues.

2. Woodworking: In woodworking, plate levellers help create a level and stable surface for precise cutting, routing, or sanding. They enhance accuracy and reduce the risk of errors.

3. Metalworking: Metalworking processes, such as welding or machining, require a level surface to achieve accurate results. Plate levellers provide a flat and stable base for these operations, ensuring precision and quality.

4. Manufacturing: Plate levellers are often integrated into manufacturing systems to level objects during production. This ensures consistent quality and reduces the likelihood of defects.

Benefits:

Using a plate leveller offers numerous advantages:

1. Precision and Accuracy: Plate levellers guarantee a level surface, resulting in precise and accurate workmanship.

2. Stability and Safety: By providing a stable base, plate levellers enhance safety and prevent accidents caused by uneven surfaces.

3. Time and Cost Savings: Level surfaces reduce the time spent on adjustments, rework, and potential errors, resulting in cost savings.

4. Versatility: Plate levellers can be used with various objects, making them versatile tools in different industries.

Plate levellers play a vital role in achieving accuracy, stability, and safety in various industries. By providing a level and balanced surface, they ensure precise workmanship, reduce errors, and enhance overall efficiency. Whether in construction, woodworking, or metalworking, plate levellers are indispensable tools that contribute to the success of countless projects. With their versatility and numerous benefits, plate levellers are an essential investment for anyone seeking excellence in their craft.

扫一扫添加微信

扫一扫添加微信