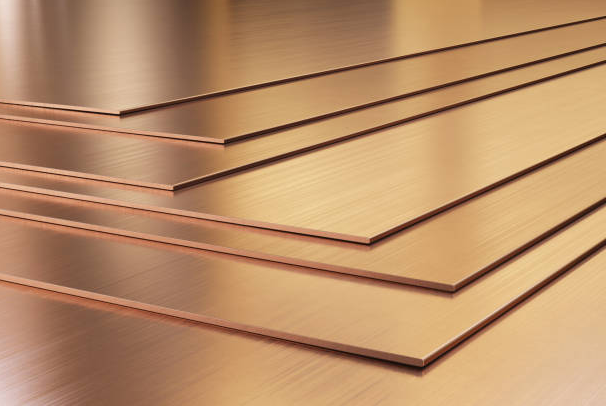

why copper plates in the electrical industry require precision leveling machines for leveling

There are several reasons why copper plates in the electrical industry require precision leveling machines for leveling:

Copper plates often require high-precision processing, and copper is a relatively soft metal material that is prone to deformation and warping during the processing, leading to a decrease in processing accuracy. Sheet metal leveling machines can correct copper plates to meet the required accuracy requirements.

In the electrical industry, copper plates are usually used to make electronic components, wires, electrical connectors, and other electrical accessories. These accessories require high-precision connection and installation, and the deformation of the copper plate can affect the accuracy and stability of the connection. The Sheet metal leveling machine can eliminate the deformation of the copper plate, ensuring the accuracy and stability of the connection.

Some copper plates in the electrical industry still require subsequent surface treatment, such as gold plating, spraying, etc. If there is significant deformation and warping of the copper plate, it will affect the subsequent surface treatment effect. Precision leveling machines can eliminate deformation of copper plates and ensure the quality of subsequent surface treatment effects.

Therefore, precision leveling machines are widely used in the electrical industry, which can improve production efficiency and product quality, reduce production costs, and are one of the important processing equipment in the electrical industry.

扫一扫添加微信

扫一扫添加微信