Sheet metal leveling

Sheet metal leveling is a process used to flatten and straighten sheet metal before it is cut and formed into different shapes and sizes. It is an essential step in the manufacturing of sheet metal products because it ensures that the final product is of high quality and meets all the required specifications.

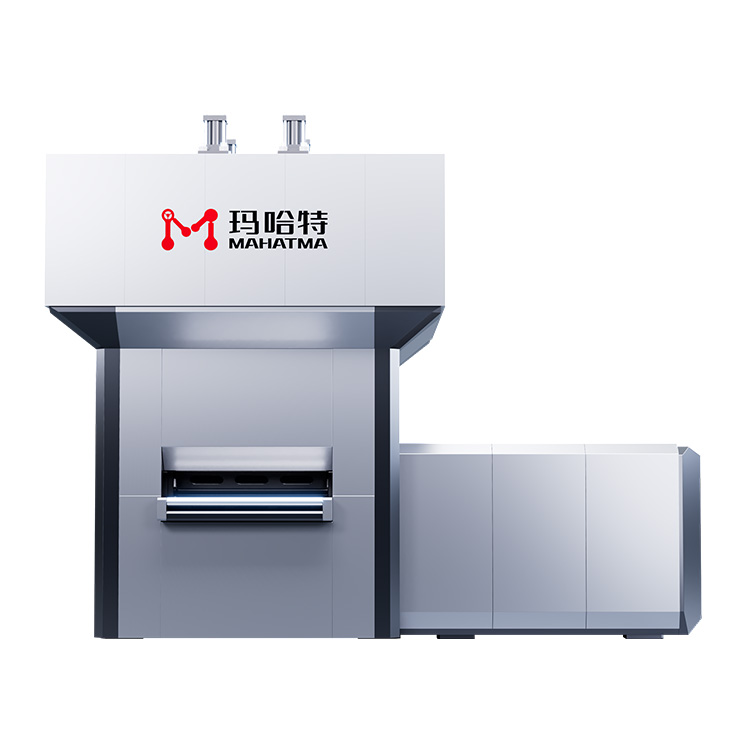

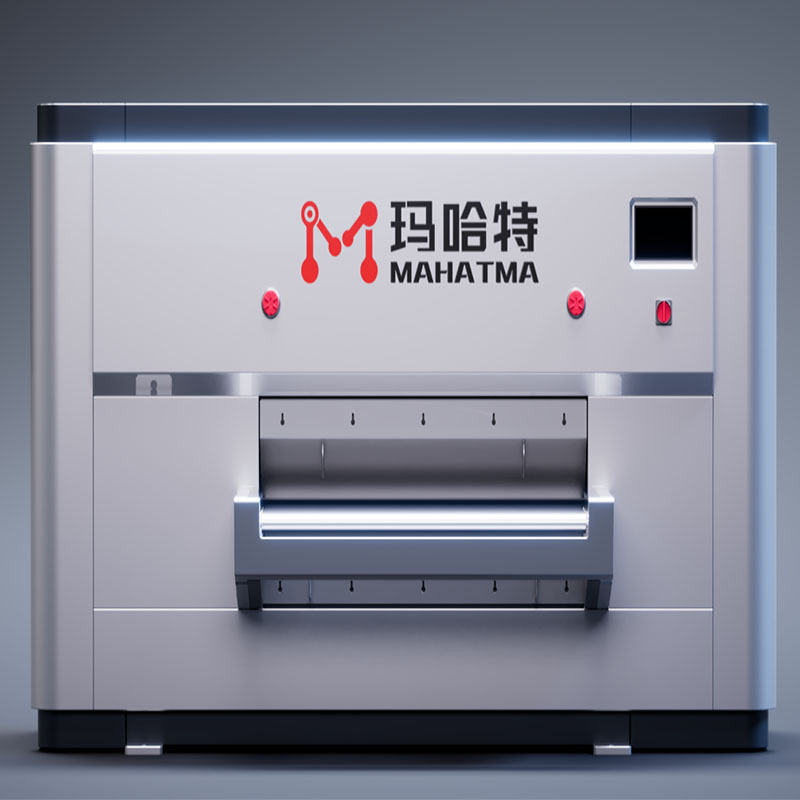

The process of sheet metal leveling involves passing the sheet metal through a leveler machine that applies pressure to the material, causing it to stretch and bend until it is perfectly flat. The leveler machine consists of a series of rollers, each with a slightly different diameter, that work together to apply pressure to the sheet metal from different angles.

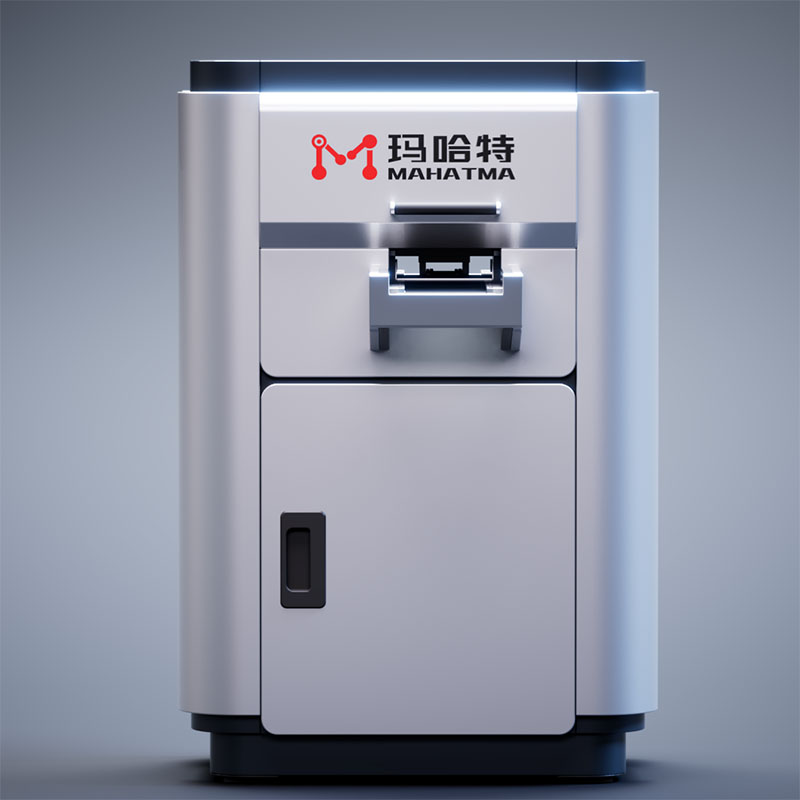

Sheet metal levelers come in different sizes and configurations, depending on the type and thickness of the material being leveled. Some levelers are designed for use with thin sheets of metal, while others can handle thicker and heavier gauges.

The main advantage of using a sheet metal leveler is that it eliminates any distortion or warping that may have occurred during the manufacturing process. This ensures that the final product is flat and even, and that it will fit properly with other components in the assembly process.

Another advantage of using a sheet metal leveler is that it can improve the overall quality and appearance of the finished product. A leveler can remove any surface imperfections or irregularities, resulting in a smooth and uniform surface.

Sheet metal levelers are also used to improve the performance of sheet metal products. By flattening and straightening the material, the leveler can improve the strength and durability of the final product, making it more resistant to wear and tear and less likely to crack or break under stress.

Sheet metal levelers are commonly used in a variety of industries, including automotive, aerospace, construction, and manufacturing. They are used to produce a wide range of products, including metal roofing, siding, HVAC ductwork, and electrical enclosures.

Choosing a suitable model for your parts

When selecting a sheet metal leveler, it is important to consider the type and thickness of the material being leveled, as well as the required level of precision and accuracy. Some levelers are designed for use with specific materials, while others are more versatile and can handle a variety of materials and gauges.

In addition to the leveler machine itself, other equipment may be required to support the leveling process. This may include decoilers, straighteners, and feeders, which work together to ensure that the sheet metal is properly aligned and fed through the leveler.

Overall, sheet metal leveling is a critical step in the manufacturing process of sheet metal products. By using a sheet metal leveler, manufacturers can ensure that their products are of high quality, meet all required specifications, and perform well in their intended applications.

扫一扫添加微信

扫一扫添加微信