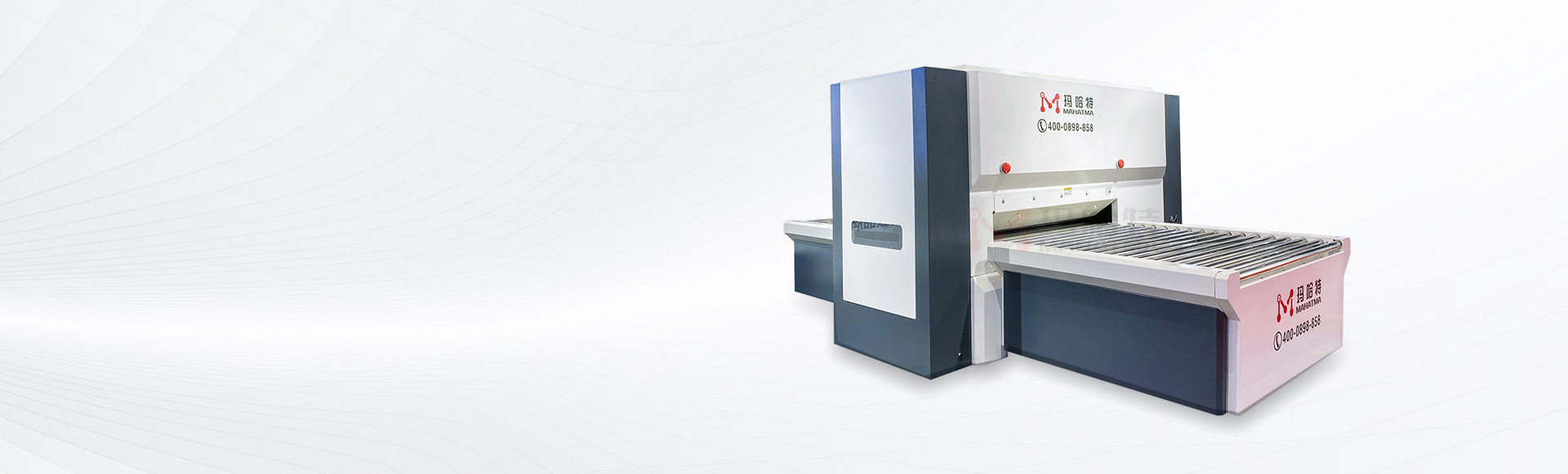

Aluminum substrate-copper substrate leveling machine (0.5-2.0mm)

The aluminum substrate/copper substrate leveling machine is covered by 13 rollers of the upper and lower rollers. The material is resistant to acid and alkali, wear and compression, and will not have any scratches on the material;

- 24-hour customer

- Guarantee

- Speed per hour

Product introduction

1. The aluminum substrate/copper substrate leveling machine is covered by 13 rollers on the upper and lower rollers.

2. The leveling inner drum is made of imported chrome steel and heat treated to HRC60. Post-grinding, then hard chrome-plating and post-grinding to ensure the uniformity of the hard chrome layer and the shape tolerance of each shaft; the surface of the drum is ground and polished to prevent the material product from being damaged by the rotation and extrusion of the drum;

3. The aluminum substrate/copper substrate leveling machine is suitable for the precise leveling of various metal 0.5-2.0mm metal strips/sheets and sheets, mainly for materials with high surface requirements such as aluminum plate, copper plate, stainless steel, etc. High leveling accuracy, not easy to deform and rebound after leveling;

4. The machine is operated by purchasing frequency conversion speed regulation, which can freely control the running speed, with buffers for start and stop, the material is not easy to shake and deform, and the surface is not easy to damage;

5. The adjustment method adopts four-point independent fine-tooth screw adjustment, controlled by four precision dial indicators, and the operation is simple and convenient;

6. The aluminum substrate/copper substrate leveling machine can be equipped with front and rear belt input and output lines or automatic roller conveyor lines;

7. The leveling accuracy can be up to plus or minus 0.05mm, depending on the product; precision dial indicator control (accurate to the drop point of 0.01mm), leveling in the form of a whole surface drop, making the leveling precision high , the speed is more convenient and simple, the leveling method is to achieve high-precision leveling effect by the internal stress of the material after the product is pressed by multiple rollers, and the highest leveling accuracy can reach 0.05mm/(diagonal 100*100mm)

8. It can cooperate with punching machine and shearing machine to realize automatic continuous production, save human resources, reduce production cost and improve work efficiency;

Product parameters

1. Width of leveling material: 0-2000mm (can be customized according to customer requirements);

2. Leveling thickness: 0.5-2.0mm;

3. The leveling head adopts pneumatic pressing, and the middle worm gear is lifted;

4. Including variable frequency speed regulation (Delta inverter);

5. It is specially designed for the leveling of single sheet material and the whole roll of material (for the convenience of customers, the design of the feeding and discharging methods of sheet material and roll material leveling is different);

6. Number of roller shafts: 13 shafts (upper 6 and lower 7) / (according to customer product requirements);

7. The leveling machine is driven by double-row chains, thickened gears, pressed by cylinders, and adjusted by worm gear lifts;

8. Leveling effect: smooth surface without indentation;

9. According to the needs of customers, the roller can be covered with rubber, which will not damage the product, the leveling precision is high, and the leveling wheel is durable and stable.

| DSHS precision leveling machine technical parameter table (Larger models can be ordered by phone) | ||||||

| type number | DSHS-200 | DSHS-400 | DSHS-500 | DSHS-600 | DSHS-800 | DSHS-1000 |

| Material Thickness | 0.5-2.0mm | |||||

| material width | 0-200mm | 0-400mm | 0-500mm | 0-600mm | 0-800mm | 0-1000mm |

| Scroll wheel diameter | φ70 | |||||

| Number of scroll wheels | Up 6 Down 7 | |||||

| flat adjustment | Manual Rotary Turbine Worm Lifter Adjustment | |||||

| Leveling Dynamics | 0.75kw | 1.5kw | 1.5kw | 2.2kw | 5.5kw | 5.5kw |

| Discharge speed | 20m/min | |||||

| speed control | Frequency debugging | |||||

| Operating Voltage | Three-phase 338V/220V | |||||

| Sensing style | Photo/electronic sensor | |||||

| Dimensions | 1.1*0.8*1.25 | 1.1*1.0*1.25 | 1.1*1.25*1.25 | 1.25*1.35*1.25 | 1.25*1.45*1.25 | 1.25*1.5*1.25 |

| device weight | 400kg | 500kg | 550kg | 650kg | 800kg | 1000kg |

add wechat

add wechat