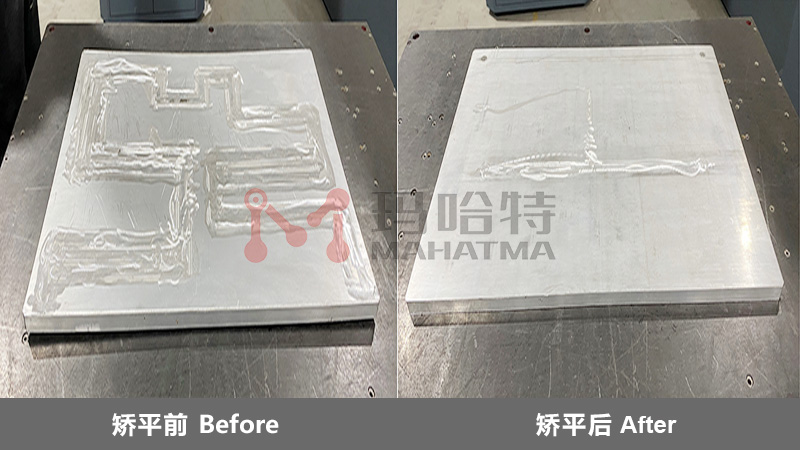

What is a metal leveling machine

Metal Leveling machine is also called part leveling machine, plate leveling machine, straightening machine, sheet leveling machine, roll leveling machine and flattening machine. Academically, it is generally called part leveling machine, but in daily life, people like to call it leveling machine.

The main structure of the leveler consists of frame, leveler wallboard, roller, support roller, heavy upper and lower bases, displacement detection device, control system, transmission system, motor reducer, electrical control system and safety protection device.

1 . The leveler is applicable to cold and hot plate, galvanized plate, aluminum plate, color coated plate, stainless steel plate and various metal parts Its operation is convenient and simple, and its application scope covers many industries such as machinery, metallurgy, building materials, chemical industry, electronics, electric power and light industry. Especially in shipbuilding, rolling stock, boiler bridge, metal structure factory and other industries, it has become an indispensable and necessary product in production.

2 . Mechanical principle of leveler:

2.1 Roller

It is finished by GCr15. After the whole drum is quenched and tempered, it is finished and reheated. The hardness is 60 ± 2 º. After grinding the surface of the drum, it is plated with hard chromium and then finely ground. The hard chromium layer on the surface is ≥ 0.1mm. The leveling roller can reduce the internal stress of the part material to the minimum, which helps the material to be processed in the next process without obstacles, and ensures the constant quality of the final product.

2.2 Support roller

The supporting roller is used to support the leveling roller to ensure that the leveling roller will not deform during the working force. It is evenly distributed in the middle of the roller group before leaving the factory, and whether it needs to be adjusted. The supporting roller is composed of multiple roller bearings in parallel, with high precision and large bearing force. The best number of supporting rollers of the leveler supports the leveler rollers, providing particularly strong support for the leveler rollers, so as to ensure the repeatable and stable leveling effect. The special design of support roll and the design of two end bearings ensure the high-precision concentric operation of support roll and improve the operation rigidity of leveling roll. It also greatly reduces the leveling lines on the part surface caused by the support roller. After leveling operation, there is no roll mark on the material surface! The stress area of the support roll is increased, and the overall heightening design of the support roll is convenient for cleaning the accumulated debris!

2.3 Control system

The electric control cabinet is centrally controlled, including the operation panel, touch screen, PLC control and electrical supporting components. The touch screen is integrated with the operation button switch to realize various functions of the leveling machine, which can easily control the direction operation of the leveling machine, adjust the leveling speed and the gap between the upper and lower leveling rollers. In the process of leveling materials, you only need to input the relevant values of the parts, such as plate thickness, pressing strength, etc. the software can easily calculate the correct position of the leveling roller frame and move it in place, and then put the parts into the machine tool for leveling. The software can set and store the material information of multiple parts (the storage capacity can be expanded infinitely according to the customer's requirements). When the same part needs to be straightened later, Just call up the value in the system and you can use it without additional debugging. The operation is simple and convenient.

2.4 Motor reducer

Leveling clearance control is realized by machinery + motor. Through the four wedge mechanism patented by mahart and multiple energy-saving actuators, there is no noise and vibration during operation (such as vibration caused by unstable hydraulic pressure in the hydraulic system). At the same time, due to the high precision of servo motor, the measurement of roll frame position can reach micron accuracy.

3 . The specific configuration of the equipment can be determined according to the number and weight of leveling machine rollers required by customers. Generally, there are two 13, 15 and 19 rollers, four 13, 15, 19 and 21 rollers and six 19, 21 and 23 rollers

4 . Application of leveling machine

Leveling machine is a common equipment in plate processing. The finalization of leveling machine depends on the thickness, material and requirements of the calibrated strip. The thicker the material, the better the structural rigidity required, the less the number of rollers, the greater the short warp, the greater the power (a certain width), and vice versa.

5. Main application of leveler

Correct plates of various specifications and plates cut into blocks. This machine is suitable for leveling all kinds of cold and hot rolled plates. Because of its convenient and simple operation, it is widely used in machinery, metallurgy, building materials, chemical industry, electronics, electric power, light industry and other industries, especially in shipbuilding, rolling stock, boiler bridge, metal structure factory and other industries.

add wechat

add wechat