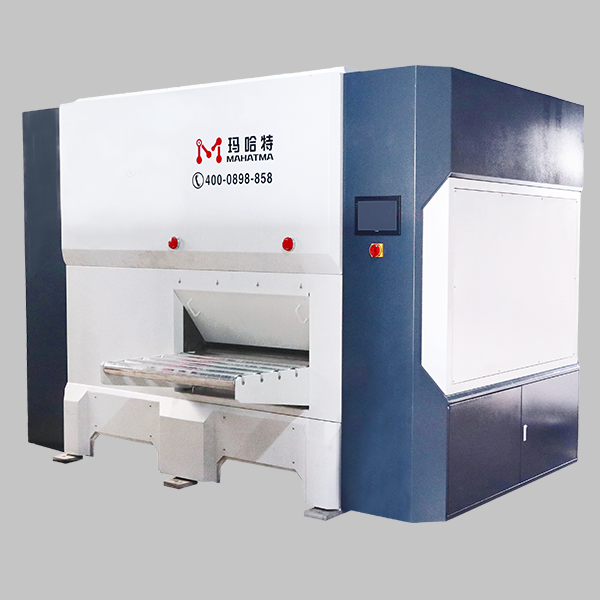

Number and weight of leveler rolls

Generally, there are double 7, 9, 11 and 13 rollers, four 11, 13, 15, 17 and 19 rollers and six 17 and 19 rollers

The roller is made of wear-resistant forged steel. With the different overall width of the equipment, each leveling roller is supported by one or more buffer idlers in its size and orientation, which can minimize the diameter of the leveling roller and reduce the spacing of the rollers. The buffer idlers can adjust the vertical orientation independently, so that they often support all loads. The surface layer of the roll has standard production and processing smoothness, but for the equipment for leveling aluminum alloy plate, the surface layer of the roll is cut and polished. In addition, there are spiral grooves on the buffer idler to gather external ash particles. The leveling roller is equipped with scraping strips to scrape off the residues adsorbed on the roller. The scraped impurities are sent to the front of the equipment according to the channel for easy collection and removal.

add wechat

add wechat