Sheet metal processing industry

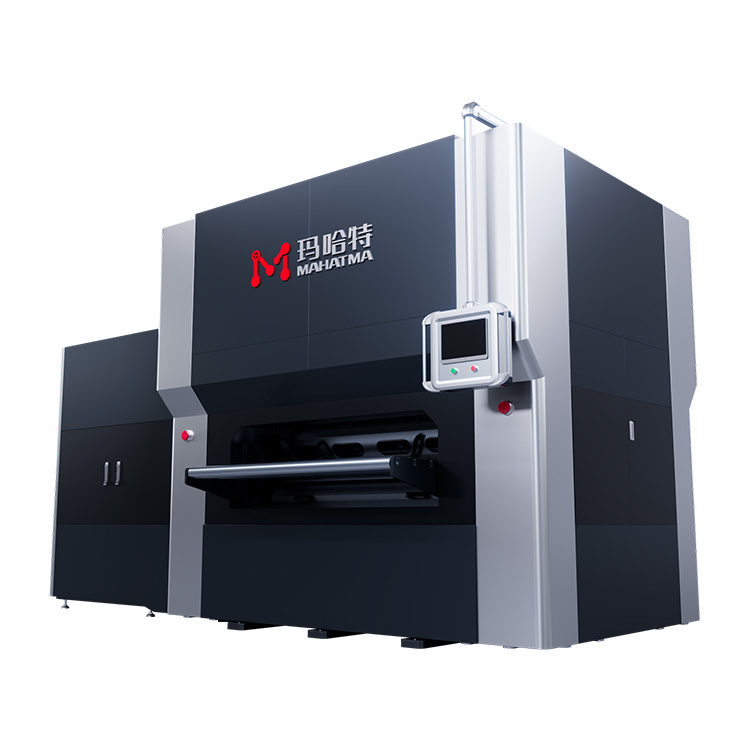

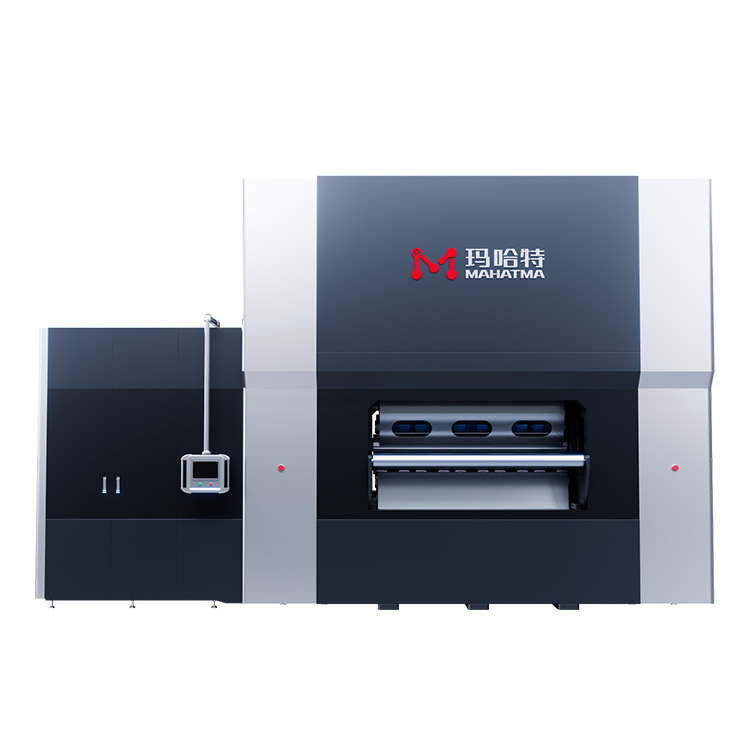

Leveling machine is a leveling equipment suitable for vehicle manufacturing, locomotive manufacturing, construction industry, medical technology industry, chassis manufacturing, textile machinery, sheet metal processing and other processing industries. It plays a vital role in the verticality, parallelism, appearance and precision of industrial structural parts!

The leveling machine has been widely used in the industry, and has the characteristics of advanced technology, high leveling accuracy, wide process range, high degree of automation, reliable and stable work under high strength, etc. Alternate bending, precise control of the pressing amount of each leveling drum through motor and PLC control, eliminates internal stress, and fundamentally solves the unsatisfactory leveling effect caused by different stresses in various parts of the plate, thus High-precision leveling is achieved.

With the advent of the era of Industry 4.0, the production model, business model and business model of the traditional manufacturing industry are facing a huge subversion. How to meet customer needs with high-quality and efficient services and economical and high-quality products in the fierce market competition has become the top priority for enterprises to break through the market. This is especially true for the sheet metal industry.

Today, the sheet metal industry cannot stick to traditional production processes, and the era of relying on manual use of hammers and flames will soon be over. To stand out from the competition in the sheet metal industry, it must provide sheet metal parts with favorable processing prices and smaller tolerances processed by advanced leveling technology. Leveling machining with a precision leveler is the solution for precise and reliable parts.

add wechat

add wechat