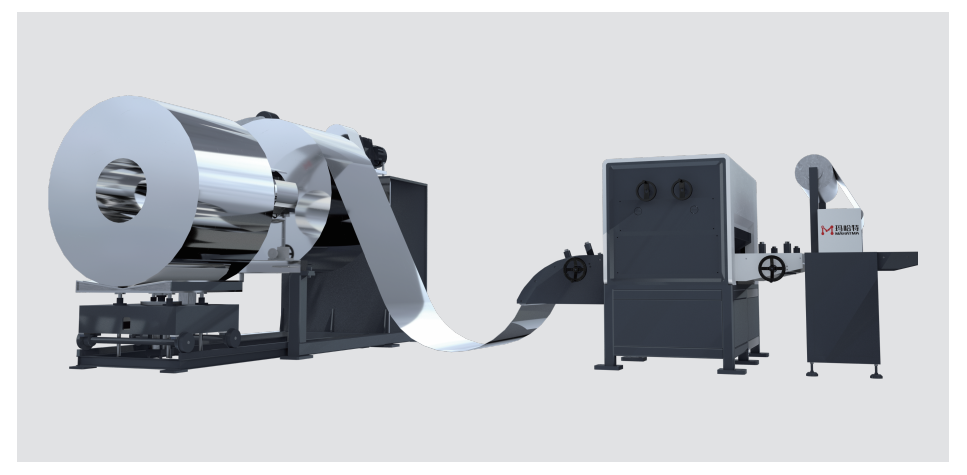

The support rod is installed, the leveling force is evenly distributed, and the structural rigidity is good High leveling accuracy, wide application range, no indentation on the surface of the material Equipped with trolley feeding, saving time and effort

Add a support rod, the leveling force is evenly distributed, and the structure is rigid

High leveling accuracy, wide application range, no residue on the material surface Indentation

With trolley loading, saving time and effort

| Shear Line Technical features | ||||

| Model | MHTS-1300M | MHTS-1500M | MHTS-2000M | MHTS-2500M |

| Maximum Width(mm) | 1300 | 1500 | 2000 | 2500 |

| Maximum Thickness(mm) | 3/6/10 | 3/6/10 | 3/6/10 | 3/6/10 |

| Roller Diameter(mm) | 60/80/120 | 60/80/120 | 60/80/120 | 60/80/120 |

| Leveling Accuracy(mm/m2) | 0.5 | 0.5 | 0.5 | 0.5 |

| Maximum Weight(t) | 5/10/15/20 | 5/10/15/20 | 5/10/15/20 | 5/10/15/20 |

| Automatic Hydraulic Feeding Trolley | Yes | Yes | Yes | Yes |

| Speed(m/min) | 0-20 | 0-20 | 0-20 | 0-20 |

| Inner Diameter(mm) | ∮508- ∮610 | ∮508- ∮610 | ∮508- ∮610 | ∮508- ∮610 |

| Maximum Outer Diameter(mm) | Φ1500 | Φ1500 | Φ1500 | Φ1500 |

| Numbers of Roller | 15 | 15 | 15 | 15 |

| Controller | Semi-automatic | Semi-automatic | Semi-automatic | Semi-automatic |

| Feeding Accuracy(mm) | ±0.2 | ±0.2 | ±0.2 | ±0.2 |

| Air Pressure(kg/cm²) | 5 | 5 | 5 | 5 |

| Rack expansion mode | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Servo Motor | Servo + Reducer | Servo + Reducer | Servo + Reducer | Servo + Reducer |

| Rack motor(kw) | 5 | 5 | 5 | 5 |

| Feeding direction | left→right | left→right | left→right | left→right |

| Feed line height(mm) | 850±50 | 850±50 | 850±50 | 850±50 |

| Voltage(v) | AC380v | AC380v | AC380v | AC380v |

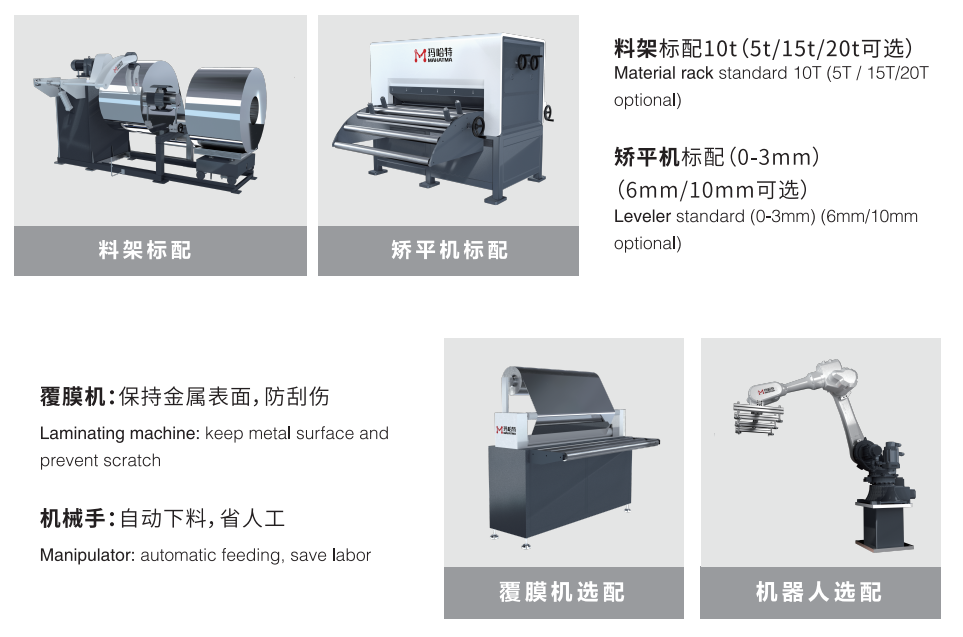

| Optional | 1. Blanking manipulator 2. Blanking joint robot 3. Automatic film laminating machine 4. Automatic stacking lifting table 5. Blanking platform | |||