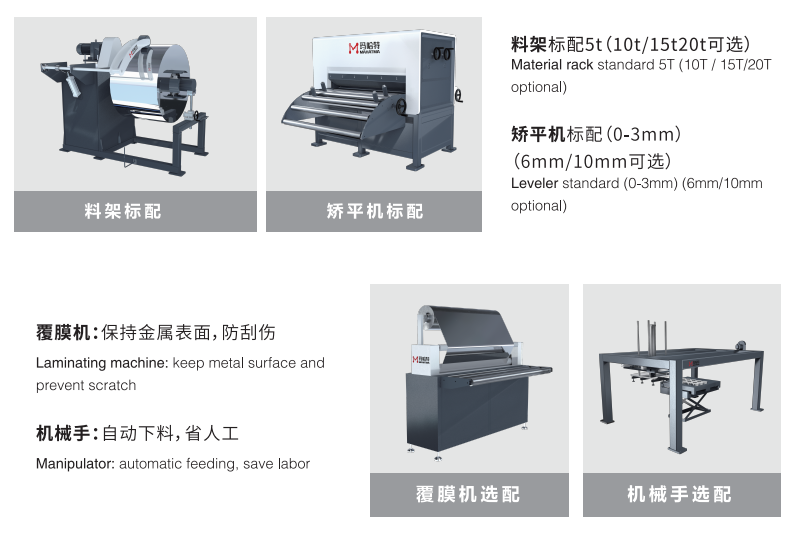

Hydraulic expansion method Accuracy of 1mm/m² is suitable for a wide range of application groups Strong structure, stable production, high cost performance

Hydraulic expansion method

Accuracy 1mm/m² is suitable for a wide range of application groups

Strong structure, stable production, high cost performance

| Shear Line Technical features | ||||

| Model | MHTS-1300H | MHTS-1500H | MHTS-2000H | MHTS-2500H |

| Maximum Width(mm) | 1300 | 1500 | 2000 | 2500 |

| Maximum Thickness(mm) | 3/6/10 | 3/6/10 | 3/6/10 | 3/6/10 |

| Roller Diameter(mm) | 60/80/120 | 60/80/120 | 60/80/120 | 60/80/120 |

| Leveling Accuracy(mm/m2) | 0.2 | 0.2 | 0.2 | 0.2 |

| Maximum Weight(t) | 5/10/15/20 | 5/10/15/20 | 5/10/15/20 | 5/10/15/20 |

| Automatic Hydraulic Feeding Trolley | Yes | Yes | Yes | Yes |

| Speed(m/min) | 0-20 | 0-20 | 0-20 | 0-20 |

| Inner Diameter(mm) | ∮508- ∮610 | ∮508- ∮610 | ∮508- ∮610 | ∮508- ∮610 |

| Maximum Outer Diameter(mm) | Φ1500 | Φ1500 | Φ1500 | Φ1500 |

| Numbers of Roller | 19 | 19 | 19 | 19 |

| Controller | CNC | CNC | CNC | CNC |

| Feeding Accuracy(mm) | ±0.2 | ±0.2 | ±0.2 | ±0.2 |

| Air Pressure(kg/cm²) | 5 | 5 | 5 | 5 |

| Rack expansion mode | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Servo Motor | Servo + Reducer | Servo + Reducer | Servo + Reducer | Servo + Reducer |

| Rack motor(kw) | 5 | 5 | 5 | 5 |

| Feeding direction | left→right | left→right | left→right | left→right |

| Feed line height(mm) | 850±50 | 850±50 | 850±50 | 850±50 |

| Voltage(v) | AC380v | AC380v | AC380v | AC380v |

| Optional | 1. Blanking manipulator 2. Blanking joint robot 3. Automatic film laminating machine 4. Automatic stacking lifting table 5. Blanking platform | |||