Structure and performance characteristics of leveling machine

The standard configuration of the leveling machine

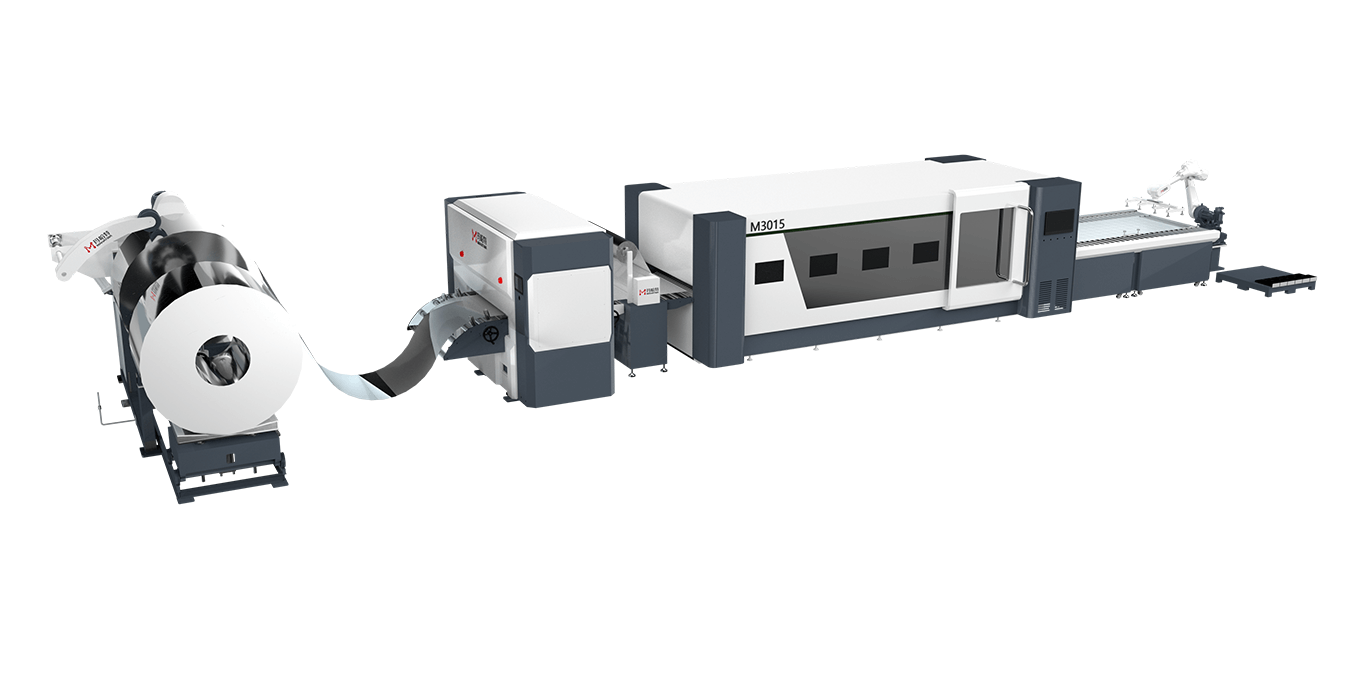

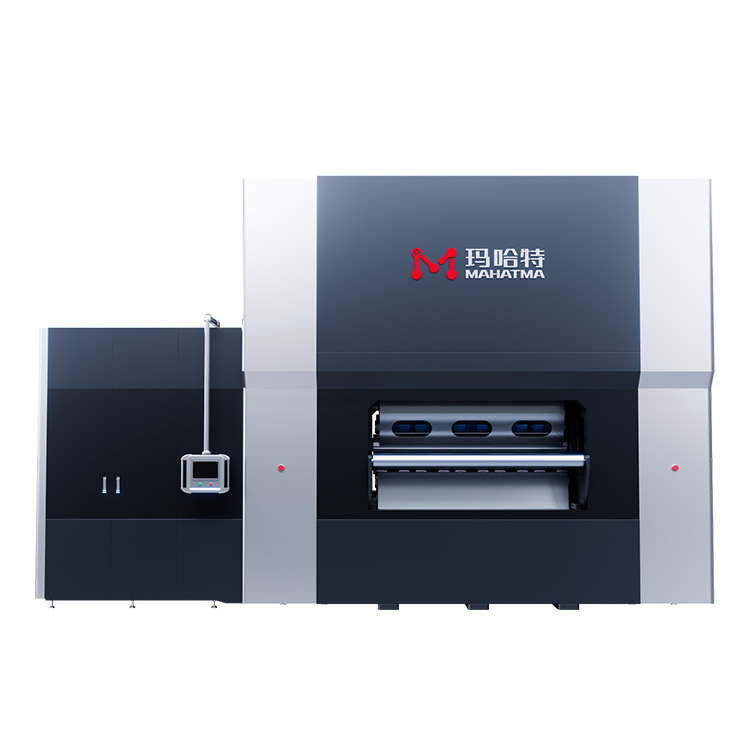

The standard configuration of parts leveler consists of: loading trolley, uncoiler, pallet pressing device, limit device, leveling host, movable bridge, limit device, sizing machine, laminating device, plate shearer, conveying workbench, pneumatic discharge rack, hydraulic lifting platform, unloading workbench, hydraulic system, electrical control system, etc; Loading trolley → uncoiler → feeding device → traction leveling machine → transition bridge → deviation correction device → servo feeding → plate shears → conveyor belt → blanking → stacking

Structure and performance characteristics of leveling machine:

1) The production line is to uncoile, level and cut cold rolled steel coil, stainless steel coil and aluminum coil into fixed size plates of various specifications.

2) The standard configuration consists of: loading trolley, uncoiler, pallet pressing device, limit device I, leveling host, movable bridge, limit device II, sizing machine, laminating device, plate shear, conveying workbench, pneumatic discharge rack, hydraulic lifting platform, unloading workbench, hydraulic system, electrical control system, etc.

3) The main components of the hydraulic system of the leveling machine production line are Taiwan high-precision components, and the sizing system is controlled by the full positioning servo system of German Lenz company. It has the characteristics of high degree of automation, good leveling quality, high shearing precision, high production efficiency, stable and reliable performance, convenient operation and maintenance, etc

add wechat

add wechat