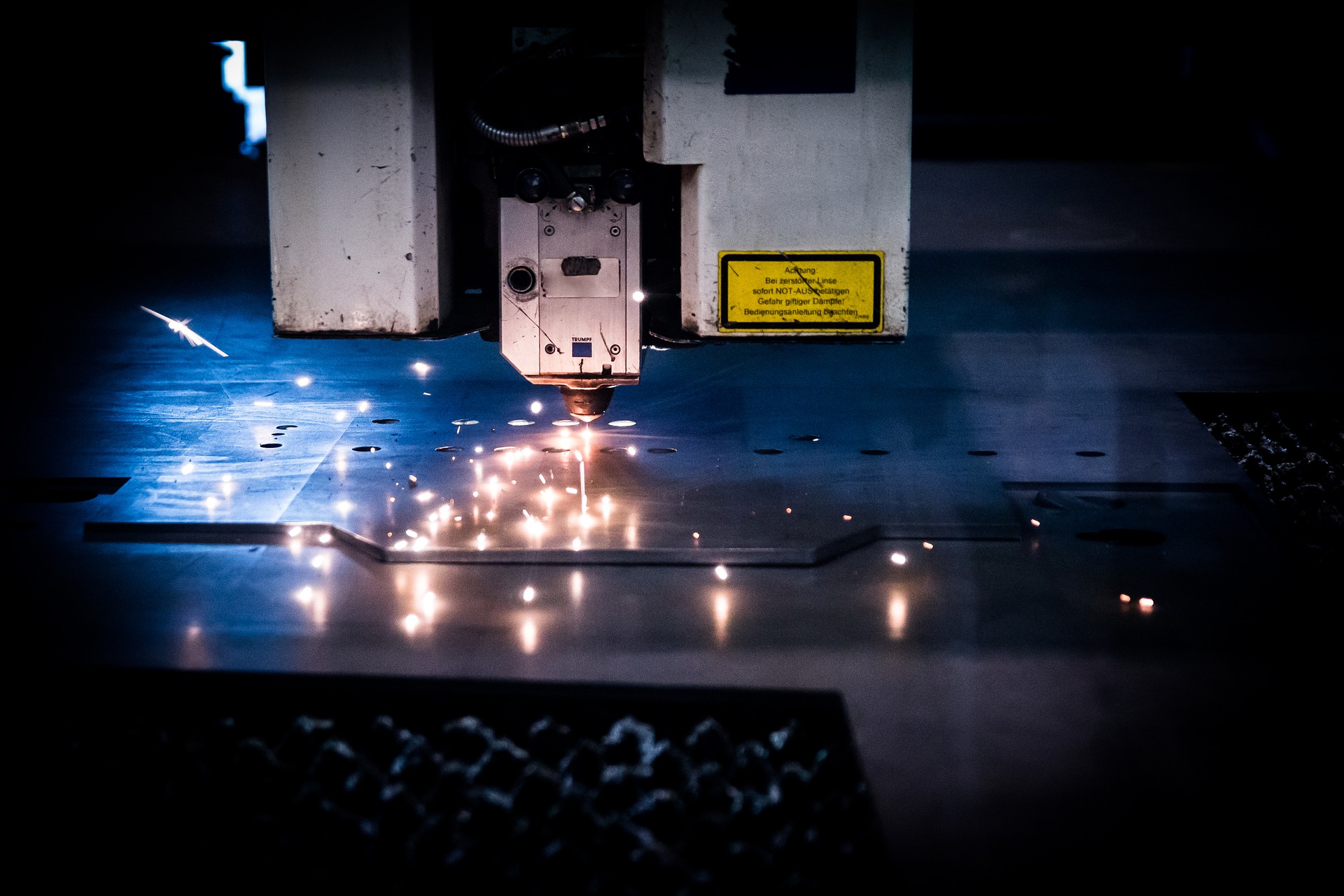

High quality machining of stainless steel sheet workpiece in laser cutting

Laser was originally called "laser" in China, which is the transliteration of English "laser". As early as 1964, according to the proposal of Academician Qian Xuesen, the beam exciter was renamed "laser" or "laser". The laser is mixed by the inert gas high-purity helium, CO2 and high-purity nitrogen in the gas mixing unit. The laser is generated by the laser generator, and then the cutting gas such as n Ω or O2 is added to irradiate the processed object. Its energy is highly concentrated in a short time to melt and gasify the material instantly. This method solves the processing difficulties of hard, extremely brittle and refractory materials, and has the advantages of high speed, high precision and small deformation. It is especially suitable for the processing of precision parts and micro parts.

In the process of laser processing, there are many factors affecting the quality of laser cutting. The main factors are composed of cutting speed, focus position, auxiliary gas pressure, laser output power and other process parameters. In addition to the above four most important variables, the factors that may affect the cutting quality include external light path, workpiece characteristics (material surface reflectivity, material surface state), cutting torch, nozzle, plate clamping, etc.

The above factors affecting the quality of laser cutting are particularly prominent in the processing of stainless steel sheet, which are as follows: there are large nodules and burrs on the reverse side of the workpiece; When the hole diameter on the workpiece reaches 1 ~ 1.5 times the plate thickness, it obviously cannot meet the roundness requirements, and the straight line at the corner is obviously not straight; These problems are also a headache for the sheet metal industry in laser processing.

1 - auxiliary gas 2 - nozzle 3 - nozzle height 4 - cutting speed 5 - melt 6 - slag 7 - cutting roughness 8 - heat affected zone 9 - slit width

Tumor accumulation problem

Shanghai Weiteli precision sheet metal processing center has done many tests repeatedly and found that the cutting support equipped with the laser cutting machine is not suitable for sheet metal processing. Main reasons: ⑴ if the R angle is large, the contact area between the top of the support and the processed plate will be large. If the laser beam is just cut on the top of the support, its splash reflection probability will be large. If the R angle is small, the splash reflection probability will be small when processing the thin plate; (2) if the distance is small and the inclination is small, the space left for the laser beam to continue to penetrate is limited, and the smaller the reflection space is, the greater the reflection force is, and the more firmly the cutting tumor adheres to the reverse side of the plate.

Based on the above considerations, we have improved the cutting support equipped with the machine tool: ⑴ the R angle is reduced, the distance from the top of the support to the base surface increases, and the slope increases accordingly. In this way, the spatter and tumor on the reverse side of the workpiece are significantly reduced, and the tumor on the reverse side can fall off by gently touching it with a tool. (2) during the cutting process, the operator found that the cutting spatter fell on the plate surface stained with oil and did not stick to the plate. It turns out that applying oil on the plate not only forms a protective film on the surface of the plate, so that the splash is not easy to stick to it; It is also conducive to the guidance of the laser beam (especially when processing plates with extremely smooth surface, such as mirror stainless steel), because the oil film is easier to absorb the laser beam compared with the smooth plate surface (the mirror panel is easy to reflect the laser beam), which is conducive to the positioning and penetration of the beam. Therefore, we evenly coat the front and back of the plate with metal rolling oil (high ignition point), so that the processed workpiece basically has no splashing and tumor accumulation, especially on the back of the workpiece, which is much better than before. (3) after repeatedly adjusting the focus position in the cutting parameters, the technicians found that the laser focus position can penetrate the plate for cutting when it is slightly less than 1 / 2 of the plate thickness, but with the deformation of the plate or the excessive cutting air pressure, the cutting quality is unstable when the thin plate is blown under large gas pressure and vibrates slightly or locally. However, when the focus is adjusted down to about 2 / 3 of the plate thickness (the focus deviation caused by deformation or shaking is corrected), the occurrence of fine burrs can be effectively avoided under the same plate and air pressure. In this way, the cutting quality of the workpiece has been greatly improved.

Small hole roundness problem

In the process of laser cutting machine cutting, holes close to 1 ~ 1.5 times the plate thickness are not easy to process with high quality, especially round holes. Laser processing requires perforation, lead wire and then cutting. Intermediate parameters need to be exchanged, resulting in instantaneous exchange time difference. This will produce the phenomenon that the round hole on the machined workpiece is not round. Therefore, we adjusted the time of perforation and lead to cutting, and adjusted the way of perforation to make it consistent with the way of cutting, so that there will be no obvious parameter conversion process.

Corner straightness problem

In laser processing, several parameters (acceleration factor, acceleration, deceleration factor, deceleration, corner residence time) that do not belong to the conventional adjustment range are the key parameters in thin plate workpiece processing. Because there will be frequent corners in the machining process of thin plate workpiece with complex shape. Slow down every time you reach the corner; After the corner, it accelerates again. These parameters determine the pause time of the laser beam somewhere:

(1) if the acceleration value is too large and the deceleration value is too small, the laser beam will not penetrate the plate well at the corner, resulting in impermeability (causing the increase of workpiece scrap rate).

If the acceleration value is too small and the deceleration value is too large, the laser beam has penetrated the plate at the corner, but the acceleration value is too small, so the laser beam stays at the acceleration and deceleration exchange point for too long, and the penetrated plate is continuously melted and gasified by the continuous laser beam, It will cause the phenomenon that the straight line at the corner is not straight (here, the factors such as laser power, gas pressure and workpiece fixation in the conventional factors affecting the cutting quality will not be considered).

(3) when processing thin plate workpiece, the cutting power shall be reduced as far as possible without affecting the cutting quality, so that there will be no obvious color difference of laser cutting and burning on the surface of the workpiece.

(4) the cutting gas pressure shall be minimized, which can greatly reduce the local micro jitter of the plate under strong air pressure.

Through the above analysis, what kind of value do we need to set to be the appropriate acceleration and deceleration value? Is there a certain proportional relationship between acceleration value and deceleration value to follow?

Therefore, technicians constantly adjust the acceleration value and deceleration value, mark each cut piece, and record the adjustment parameters. After repeatedly comparing the samples and carefully studying the changes of parameters, it is finally found that when cutting stainless steel in the range of 0.5 ~ 1.5mm, the acceleration value is between 0.7 ~ 1.4g, the deceleration value is between 0.3 ~ 0.6g, and the acceleration value = deceleration value × About 2 is better. This rule is also suitable for cold-rolled plates with similar plate thickness (for aluminum plates with similar plate thickness, the value must be adjusted accordingly).

Concluding remarks

After successfully solving the above factors affecting the cutting quality, the stainless steel sheet products processed by us have been greatly improved in terms of cutting tumor accumulation and cutting fineness. As a contemporary technical worker, we should be willing to study, dare to climb, and adhere to the concept of "excellence and perfect manufacturing", so as to make high-quality products and make them stand in the fierce economic competition.

add wechat

add wechat