Coil H series

This machine adopts Japan\'s Panasonic PLC controller, which has the function of storing, calling and editing process parameters. It can set the reduction amount of the inlet and outlet according to the parameters such as plate thickness and plate width or the existing parameters in the database, so as to realize the gap between the out and in of the work roll. electric adjustment of Leveling accuracy up to 0.2mm/㎡

- 24-hour customer

- Guarantee

- Speed per hour

Product introduction

This machine adopts Japan's Panasonic PLC controller, which has the function of storing, calling and editing process parameters. It can set the reduction amount of the inlet and outlet according to the parameters such as plate thickness and plate width or the existing parameters in the database, so as to realize the gap between the out and in of the work roll. electric adjustment of

Leveling accuracy up to 0.2mm/㎡

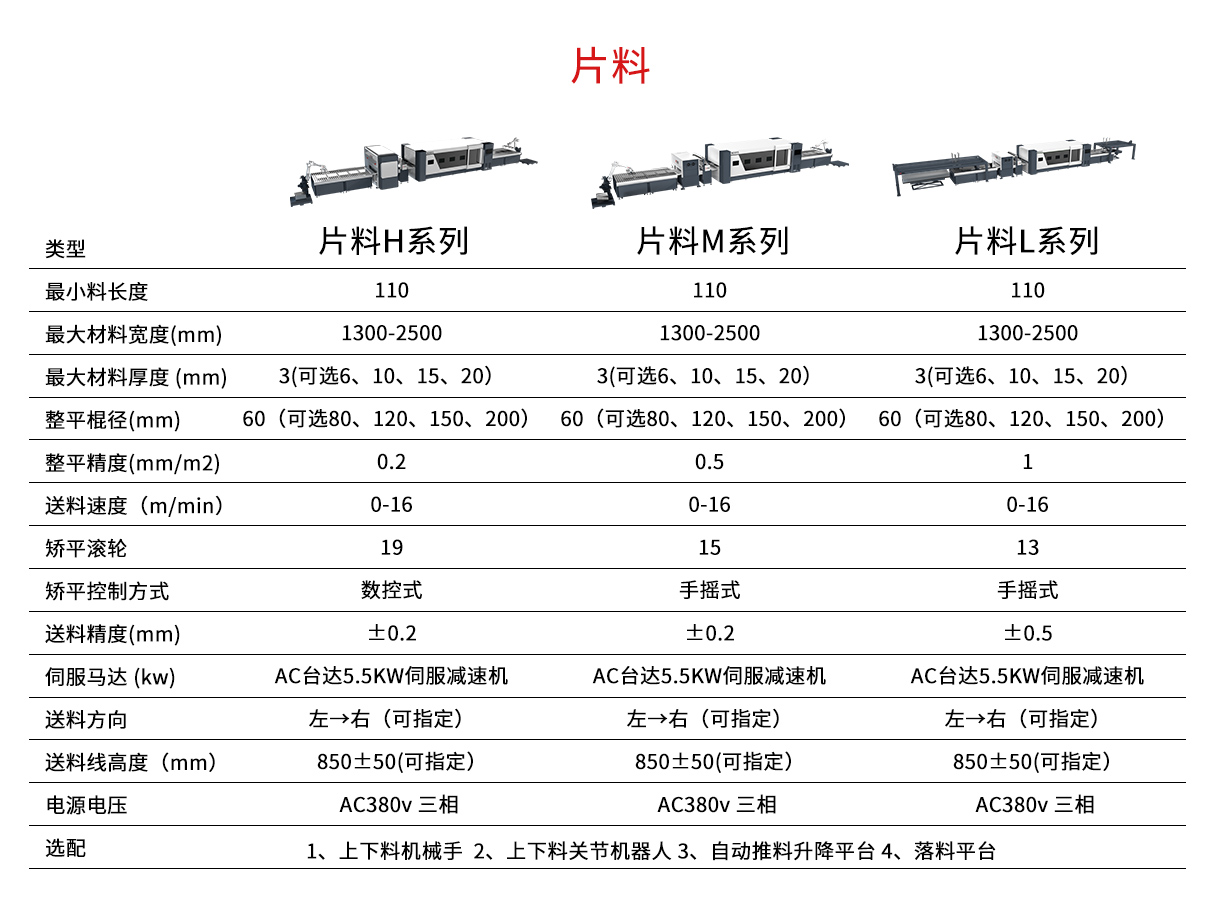

Product parameters

| Shear Line Technical features | ||||

| Model | MHTS-1300L | MHTS-1500L | MHTS-2000L | MHTS-2500L |

| Maximum Width(mm) | 1300 | 1500 | 2000 | 2500 |

| Maximum Thickness(mm) | 3/6/10 | 3/6/10 | 3/6/10 | 3/6/10 |

| Roller Diameter(mm) | 60/80/120 | 60/80/120 | 60/80/120 | 60/80/120 |

| Leveling Accuracy(mm/m2) | 1 | 1 | 1 | 1 |

| Maximum Weight(t) | 5/10/15/20 | 5/10/15/20 | 5/10/15/20 | 5/10/15/20 |

| Automatic Hydraulic Feeding Trolley | No | No | No | No |

| Speed(m/min) | 0-20 | 0-20 | 0-20 | 0-20 |

| Inner Diameter(mm) | ∮480- ∮530 | ∮480- ∮530 | ∮480- ∮530 | ∮480- ∮530 |

| Maximum Outer Diameter(mm) | Φ1500 | Φ1500 | Φ1500 | Φ1500 |

| Numbers of Roller | 13 | 13 | 13 | 13 |

| Controller | Semi-automatic | Semi-automatic | Semi-automatic | Semi-automatic |

| Feeding Accuracy(mm) | ±0.2 | ±0.2 | ±0.2 | ±0.2 |

| Air Pressure(kg/cm²) | 5 | 5 | 5 | 5 |

| Rack expansion mode | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Servo Motor | Servo + Reducer | Servo + Reducer | Servo + Reducer | Servo + Reducer |

| Rack motor(kw) | 5 | 5 | 5 | 5 |

| Feeding direction | left→right | left→right | left→right | left→right |

| Feed line height(mm) | 850±50 | 850±50 | 850±50 | 850±50 |

| Voltage(v) | AC380v | AC380v | AC380v | AC380v |

| Optional | 1. Blanking manipulator 2. Blanking joint robot 3. Automatic film laminating machine 4. Automatic stacking lifting table 5. Blanking platform | |||

add wechat

add wechat