Leveling machine improve the quality of metal parts

Sheet metal parts have different shapes and thicknesses in different application fields. Each sheet metal needs an accurate and fixed shape to ensure that it can reliably pass through various downstream production processes. It needs to be suitable for all kinds of trouble free, repeatable and efficient manufacturing. In this case, the role of leveling process in sheet metal processing process is particularly important. In this article, we will share with you why and how to improve the quality of plates and parts.

Find the correct internal stress

Each plate has its internal stress, which affects the quality and reliability of subsequent manufacturing process. However, they are often difficult to measure, usually only through the unevenness or deformation of the plate surface. Sometimes it is not easy to be seen by the naked eye, and its disadvantages will be highlighted only when welding, milling or bending. And it is often difficult to determine how much residual stress remains in the leveled plate.

Therefore, it is not easy for some decision makers to evaluate the actual benefits of leveling plates. Generally speaking, the smaller the internal stress of the plate, the more accessible the manufacturing and the higher the efficiency. For example, when processing materials, welders will exclaim: the leveled plate is not only flat and easy to operate, but also greatly reduces the assembly time. Secondly, the dimensions are more accurate during assembly and there is no need to rework. This result is helpful to the formulation of production quality and production plan. For decision makers, the benefits of these leveling will also be reflected in the saving of production cost.

In addition to the internal stress of the plate itself, stress and uneven areas will also occur in the manufacturing process. Just like laser or plasma thermal cutting, a large amount of heat will be generated at the cutting edge, forming a temperature gradient and causing stress. At the same time, it also hardens the edges. The result is that the parts are deformed, which hinders the effective downstream processing. At this time, the only way to solve this problem is leveling.

High efficiency leveling

Plate deformation and unevenness will lead to a large number of rework in the later stage, a sharp increase in the number of unqualified parts, and have a negative impact on the efficiency of the manufacturing process. This is neither economical nor conducive to improving customer satisfaction and competitiveness. Leveling can prevent these problems, and roller leveling has been proved to be the most efficient method. Because it is not only applicable to the rapid and simple leveling of sheet metal parts and plates, the core point is that it scientifically reduces the unevenness and internal stress in the material through the process of alternating bending.

The leveling machine used in production must have the following characteristics to achieve the best leveling effect: the leveling working unit is designed as a module, the layout of leveling roll and support roll is correct, and a certain number of rolls and roll diameter. The principle is: the smaller the roll diameter, the more leveling rolls the equipment should be equipped with. Small roll diameter and roll spacing are very important to meet the requirements of high precision flatness. In addition, the leveling roller itself needs very good support to ensure that the plate is rolled continuously, and the plate will not slide between the work rollers and produce waves. If you want to process the highest quality plate parts, the number of leveling rollers in the leveling machine is an important factor that you must pay attention to.

Leveling ensures consistent high quality standards

In the sheet metal manufacturing industry, the quality of products determines the success and future prospects of enterprises. This requires high standards and strict requirements for each sheet metal part processed, which is why the leveling process must become an integral part of your high-quality production.

You can also get huge benefits from using automatic leveling. Through standardized and automated processes, roller leveling ensures consistent high-quality results. Compared with manual leveling, the production efficiency is greatly improved.

Abandoning the leveling process was a risky decision

The use of roller leveler for part leveling has a decisive advantage, which your customers know very well. They usually adopt standardized production processes and rely heavily on smooth downstream processing.

The UN leveled plate may cause angle error in the next process (such as edge banding and bending), which will increase the number of rework and nonconforming products. At the same time, welding becomes very time-consuming. When welding robots are used, such materials will also have a negative impact on process reliability and welding time, which will lead to higher process cost and increased heat on materials, bring stress into materials and lead to deformation. Correcting this phenomenon requires rework and longer production cycle, which is very unfavorable to the process efficiency.

Perfect sheet metal brings satisfied customers

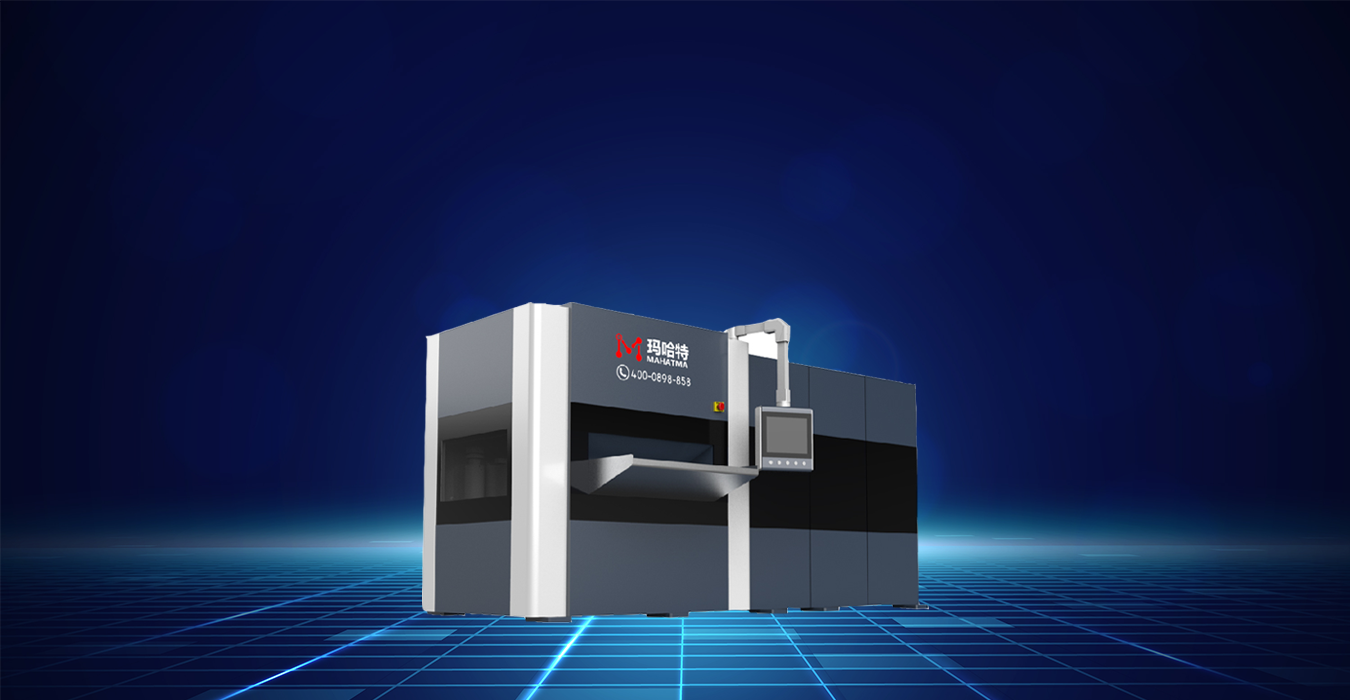

Different customers have different needs. It is particularly important to ensure the best processing technology while ensuring the quality. Flattening sheet metal parts not only eliminates stress and repairs flatness defects, but also reduces possible problems in downstream processing. High quality sheet leveler can help you get high-quality leveling effect quickly and reliably. It can automatically calculate the correct settings, and the operator only needs to make some minor adjustments at most. In addition, our sheet leveler also has the function of automatically detecting flatness. With the correct automation device, it can realize autonomous leveling processing in many application fields. Use MAHATMA leveler to level your sheet metal parts, immediately obtain perfect flatness, and improve the quality of sheet metal parts and your market competitiveness.

add wechat

add wechat