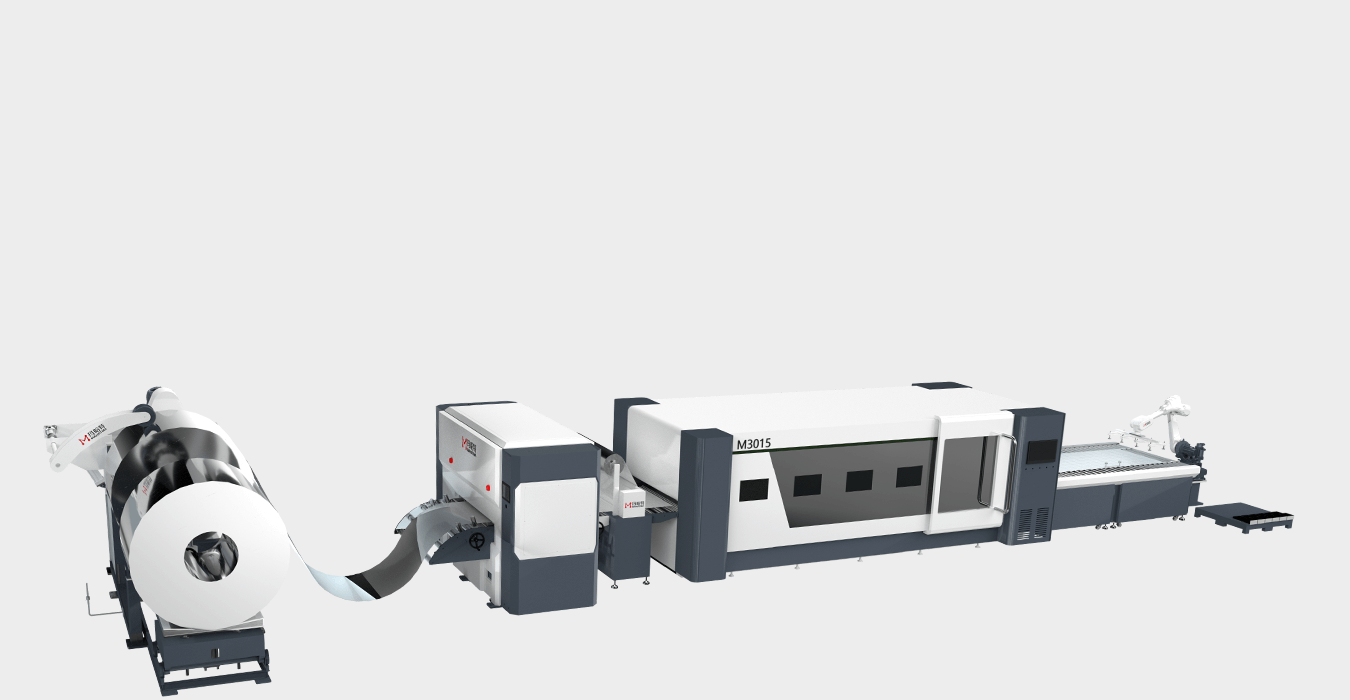

Uncoiling and leveling longitudinal shear line

Generally, there are three production lines for the opener, which are

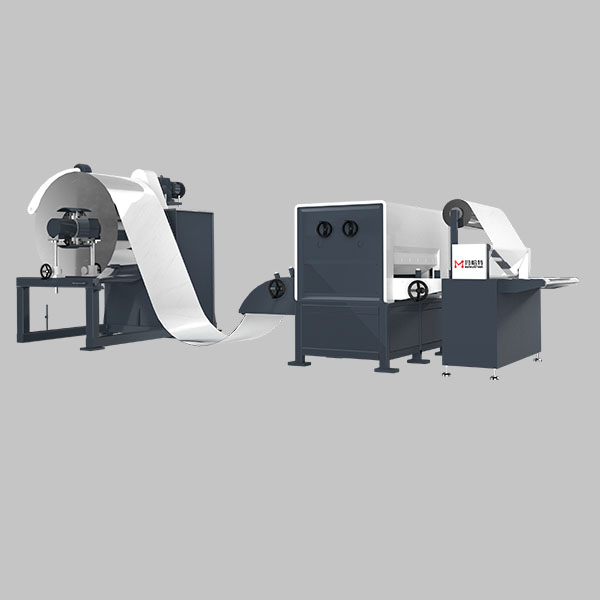

1. Uncoiling leveling cross cutting stacking production line

2. Uncoiling slitting leveling winding production line

3. Uncoiling - leveling - longitudinal shear - winding / sizing - transverse shear composite production line

Uncoiling slitting leveling winding production line:

The leveling line is applicable to the uncoiling and leveling of cold-rolled, hot-rolled steel coils and low-alloy coils with medium thickness, which are divided into narrow coils of various specifications or cut into fixed-length plates of various specifications.

It is composed of trolley, slitting head, hydraulic straightening machine, hydraulic control system of slitting head, slitting head, hydraulic straightening machine, hydraulic control system, etc. There are three configurations for users to choose from,

1: Uncoiling - leveling - slitting - winding

2: Uncoiling - leveling - longitudinal shear - sizing - transverse shear

3: Composite wire with the above two functions

The main components of the hydraulic system of the production line adopt high-precision components, and the electrical control adopts imported PLC program controller and touch screen to control the functions of the whole line. It has the characteristics of high degree of automation, good leveling quality, high cutting precision, stable and reliable performance, convenient operation and maintenance, etc. the coil feeding at one time can realize the smooth completion of each process, effectively reduce the labor intensity of workers, and has high cost performance. It is a combination of machine, electricity Liquid integrated high-performance products.

Customized standard

◆ the whole machine has reasonable design structure, compact shape, high precision, high efficiency, flexible and convenient adjustment

◆ the frame is welded with steel plate and annealed. It is processed by CNC machining center to ensure high strength and high precision

◆ the manufacturing process of the whole machine is produced in strict accordance with the mechanical design specifications, and the leveling roller is made of bearing steel GCr15

◆ the working shaft support of the whole machine adopts heavy-duty bearing, combined with advanced lubrication system, with long service life

◆ PLC control of the whole line, touch screen display and operation, high degree of automation

◆ electrical components are of foreign high-grade brands, and mechanical accessories are domestic well-known brands

add wechat

add wechat