The precision leveling machine assembly line is a reinforced high-precision sheet material precision leveling machine, which is suitable for precision roller leveling of metal sheets and strips with a thickness of 0.5-3.0mm;

1. The precision leveling machine assembly line is a reinforced high-precision sheet material precision leveling machine, which is suitable for precision roller leveling of metal sheets and strips with a thickness of 0.5-3.0mm;

2. The leveling machine line is a multi-roller precision thick plate leveling machine. The leveling rollers are 6 on the top and 7 on the bottom, and two auxiliary support rollers are installed on each of the upper and lower rollers;

3. The leveling wheel and back pressure wheel of the precision leveling machine produced by our company are all made of imported chrome steel and heat treated to HRC60. Post-grinding, then hard chrome-plating and post-grinding to ensure the uniformity of the hard chrome layer and the shape tolerance of each shaft; the surface of the drum is ground and polished to prevent the material product from being damaged by the rotation and extrusion of the drum;

4. There are two adjustable springs on the feeding upper drum of the leveler assembly line to adjust the feeding pressure, and manually adjust the feeding gap to make the feeding smoother;

5. The adjustment and leveling of the parts is adjusted by the turbine elevator, controlled by four precise digital dial indicators (accurate to the drop point of 0.01mm), and leveled in the form of the whole surface falling, which makes the leveling precision high and the speed adjustment more accurate. Convenient and simple, the leveling method is the high-precision leveling effect achieved by the internal stress of the material after the product is pressed by multiple rollers.

6. The leveling speed of the leveling machine assembly line is 0-15m/min, and the Delta frequency converter is used to adjust the speed by frequency conversion, and the manual knob can be adjusted according to the needs;

7. The precision leveling machine line is suitable for high-precision leveling of metal sheets or punched materials. Auxiliary stainless steel pallets are installed at the inlet and outlet of the machine to facilitate the handling of sheet products in and out;

8. Double row chain drive, thickened gears.

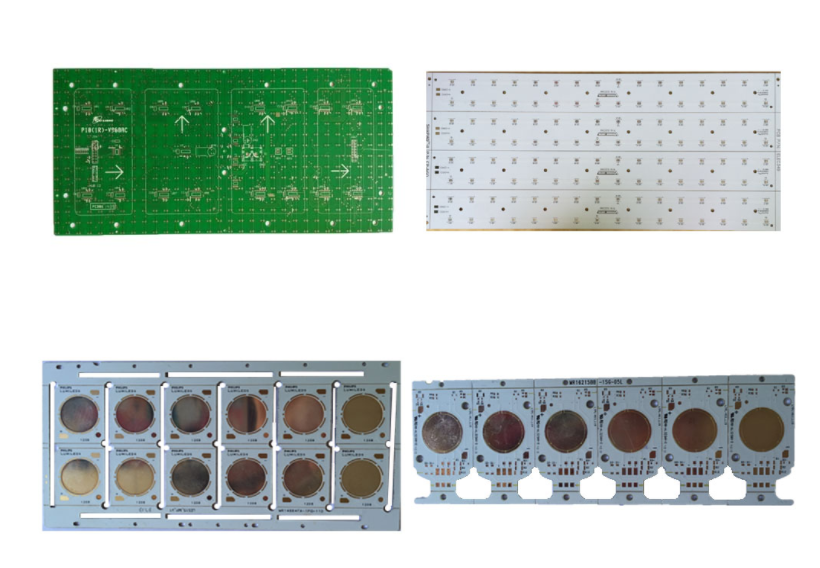

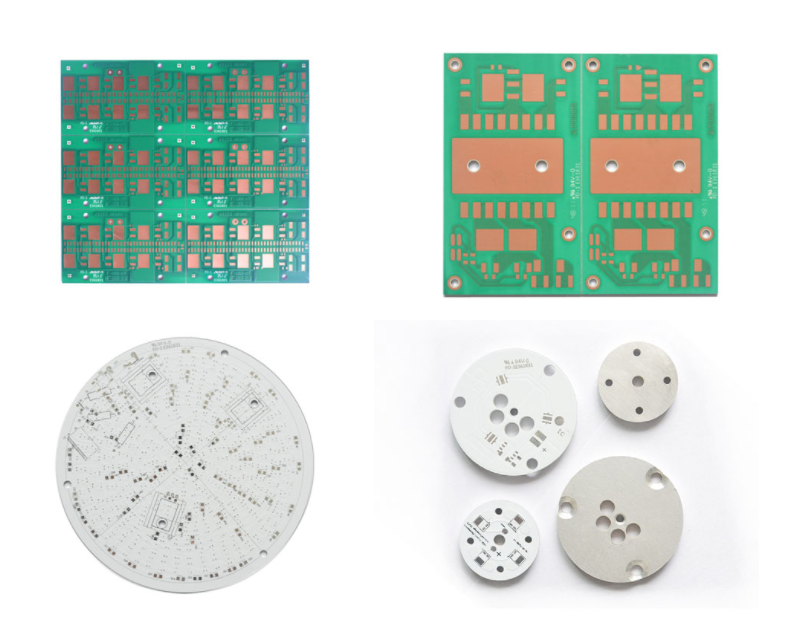

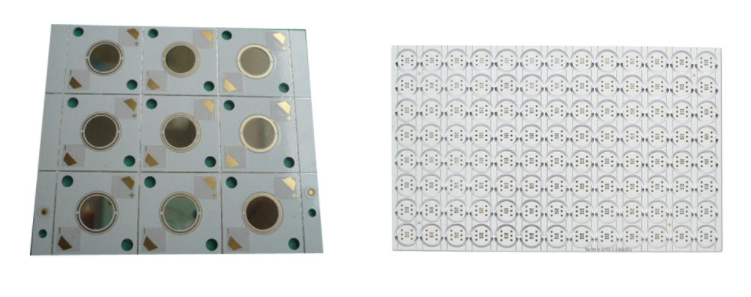

Aluminum substrate precision leveling machine - leveling sample display:

1. Width of leveling material: 0-2000mm (can be customized according to customer requirements);

2. Leveling thickness: 0.5-3.0mm;

3 The leveling head adopts pneumatic pressing, and the middle worm gear is lifted and lowered;

4 Including variable frequency speed regulation (Delta inverter);

5 It is specially designed for the leveling of single sheet material and the whole coil material (for the convenience of customers, the design of the feeding and discharging methods of sheet material and coil material leveling is different);

6 Number of roller shafts: 13 shafts (upper 6 and lower 7)/according to customer product requirements;

7. Double-row chain drive of the leveler, thickened gears, cylinder pressing, and worm gear lift adjustment;

8. Leveling effect: smooth surface without indentation;

According to the needs of customers, the roller can be covered with rubber, which will not damage the product, the leveling precision is high, and the leveling wheel is durable and stable.

| Precise adjustment Flat machine LSHS series technical parameter table (larger models can be customized by calling) | ||||||

| type number | LSHS-200 | LSHS-400 | LSHS-500 | LSHS-600 | LSHS-800 | LSHS-1000 |

| Material Thickness | 0.5-3.0mm | |||||

| material width | 0-200mm | 0-400mm | 0-500mm | 0-600mm | 0-800mm | 0-1000mm |

| wheel diameter | φ70 | |||||

| Number of scroll wheels | Up 6 Down 7 | |||||

| Flat Adjustment | Manual Rotary Turbine Worm Lifter Adjustment | |||||

| Leveling Dynamics | 0.75kw | 1.5kw | 1.5kw | 2.2kw | 5.5kw | 5.5kw |

| Discharge speed | 15m/min | |||||

| speed control | Frequency debugging | |||||

| Operating Voltage | Three-phase 338V/220V | |||||

| Sensing method | Photo/electronic sensor | |||||

| Dimensions | 1.1*0.8*1.25 | 1.1*1.0*1.25 | 1.1*1.25*1.25 | 1.25*1.35*1.25 | 1.25*1.45*1.25 | 1.25*1.5*1.25 |

| device weight | 400kg | 500kg | 550kg | 650kg | 800kg | 1000kg |